1. Introduction: Why Accurate Box Measurement Matters

Getting the right box size is more than just a detail—it’s essential to ensuring your product fits, your packaging looks professional, and your shipping costs stay low.

Whether you’re ordering custom printed boxes or simple mailers, accurate measurements help your packaging supplier deliver exactly what you need. Incorrect sizing can lead to product damage, wasted materials, or increased freight costs.

If you’re working with custom packaging manufacturers, always start by measuring your box the right way.

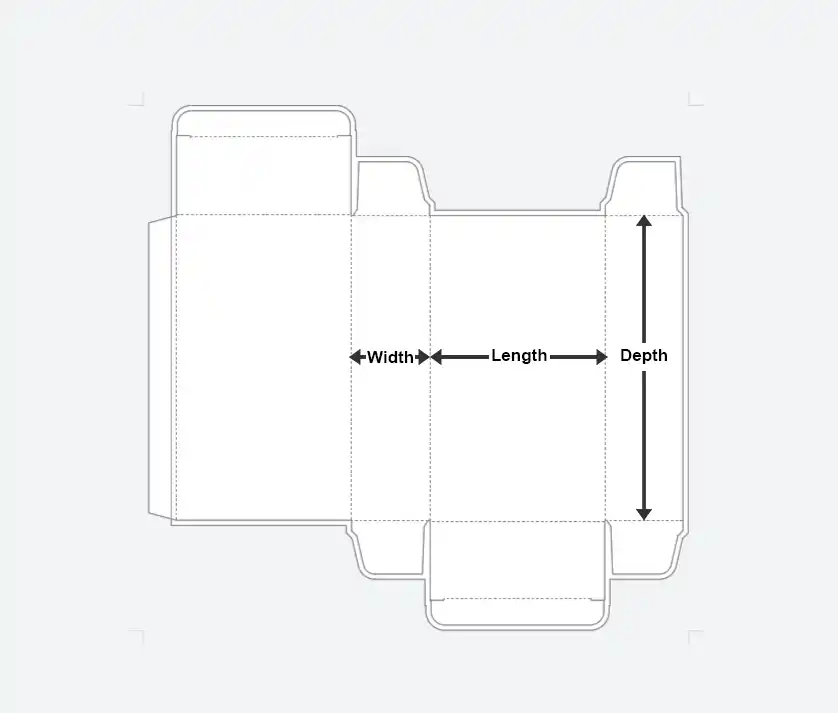

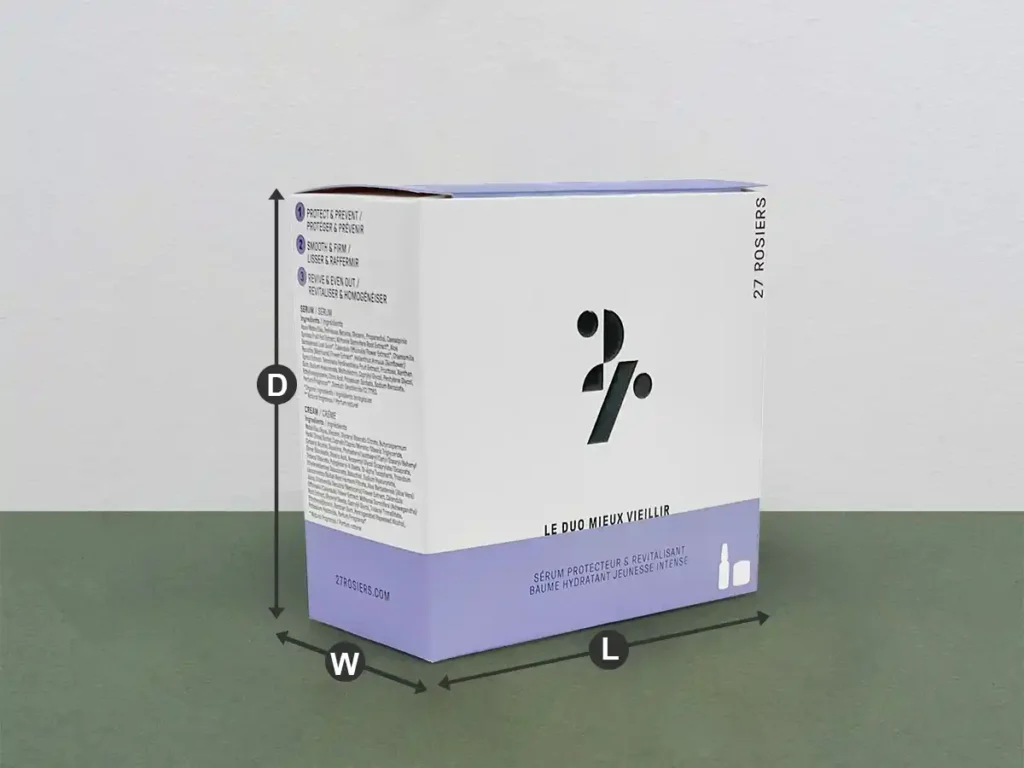

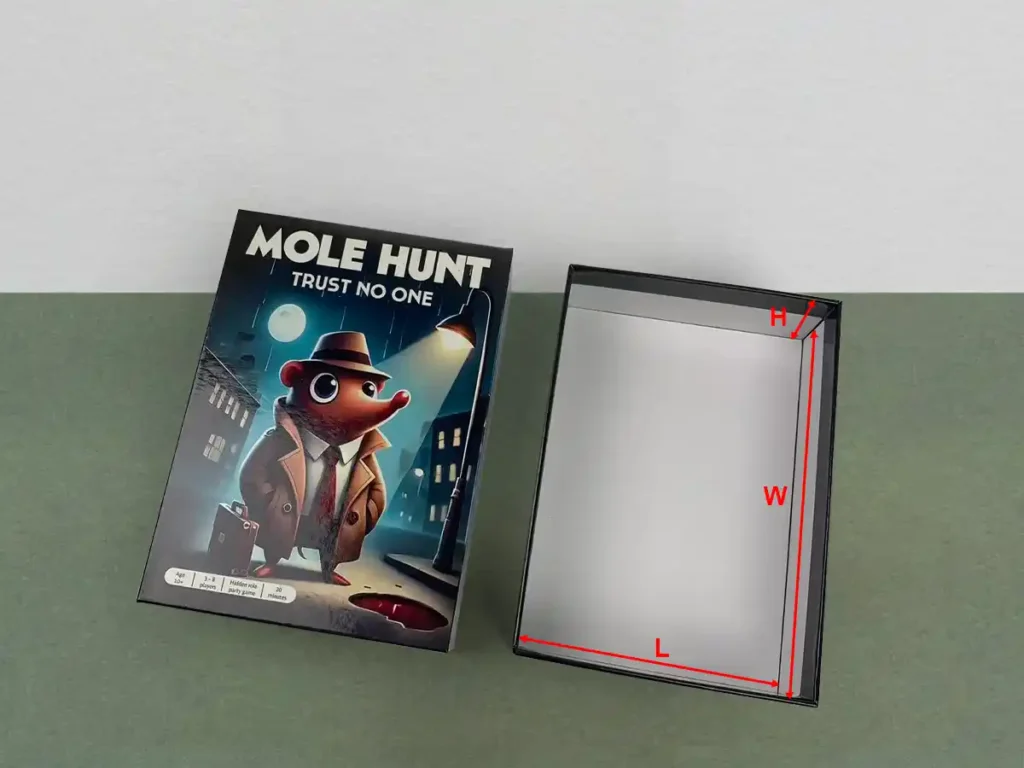

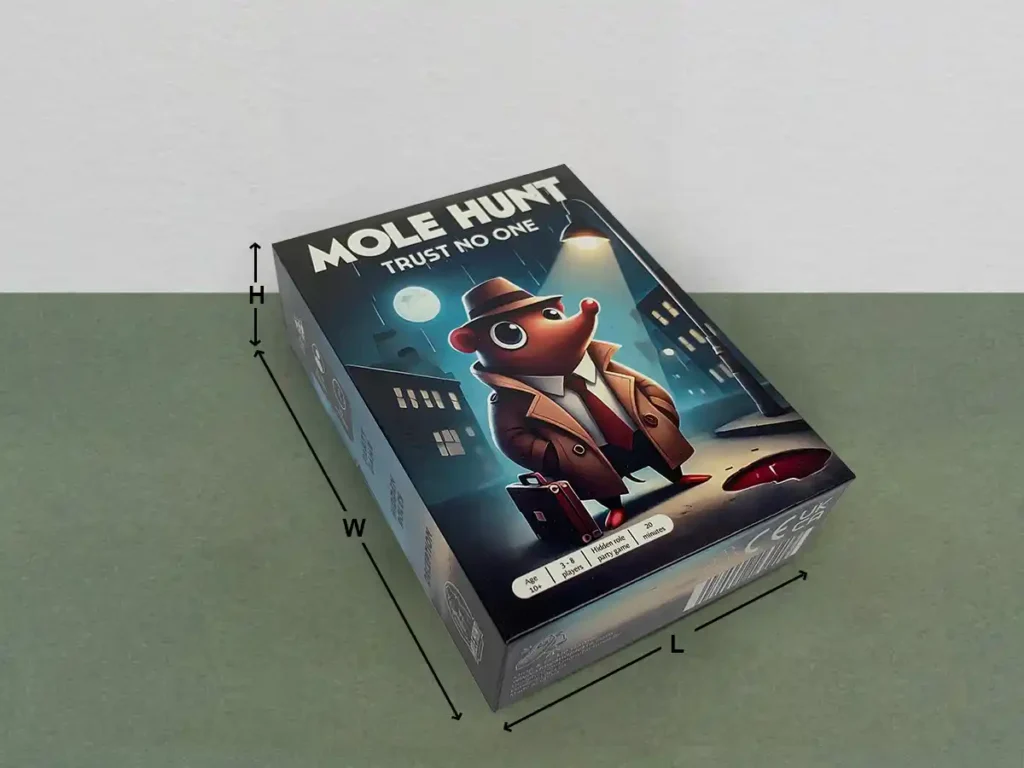

2. Understand Box Dimensions: Length × Width × Height

Box dimensions are listed in a specific order:

Length × Width × Height (also called Depth).

- Length – The longest side of the box (left to right when the box is facing you)

- Width – The shorter side of the base (front to back)

- Height – The vertical side (from bottom to top)

📌 Tip: Always measure the box when it’s standing upright and open at the top. This helps you avoid confusion between height and width.

3. Internal vs. External Dimensions

When measuring boxes, it’s important to know the difference:

- Internal Dimensions refer to the usable space inside the box. These are most commonly used for product fit.

- External Dimensions refer to the outside of the box. These matter for shipping, shelving, and storage.

📦 Use internal dimensions when you’re designing a box to hold your product.

🚚 Use external dimensions when calculating shipping size or warehouse storage.

Always clarify which measurement type you’re providing to your packaging supplier.

4. How to Measure a Box (Step-by-Step)

To ensure your packaging fits perfectly, box dimensions must be measured accurately. The standard format is always:

➤ L × W × D

Where:

- L (Length): The side running left to right when the box is facing forward

- W (Width): The side running front to back

- D (Depth/Height): The vertical side from bottom to top

This naming convention stays the same across different box styles—whether it’s a folding carton, rigid box, mailer, or display tray.

The image below shows how length, width, and depth are positioned for various types of packaging boxes:

5. Common Mistakes to Avoid

Even small errors in measuring a box can lead to big issues later in production or delivery. Here are some of the most common mistakes—and how to avoid them:

❌ Mixing Up Dimensions

Always follow the standard order: Length × Width × Height. Swapping these can result in a completely different box.

❌ Using Outside Measurements for Product Fit

External dimensions don’t account for box wall thickness. If you need your product to fit snugly, use internal measurements.

❌ Measuring a Closed Box

If the flaps are down or the box is folded, your measurements might be off. Always measure with the box fully assembled and open.

❌ Ignoring Unit Consistency

Double-check your unit of measurement—millimeters (mm), centimeters (cm), or inches (in)—especially when working with international suppliers.

6. Final Tips Before Sending Your Specs

Before placing your order, take a moment to review and confirm the details below:

✅ Confirm the Box Style

Different styles (mailer, folding carton, rigid box) may require different measurements. Check with your packaging supplier for guidelines.

✅ Check Your Units

Use the unit your supplier requests—most commonly mm or inches—and stay consistent throughout your spec sheet.

✅ Double-Check All Three Dimensions

If you’re not sure which side is length, width, or height—ask. Sending a drawing or sample helps prevent miscommunication.

7. Quick Recap: Box Measurement FAQ

Q: What is the correct order for box dimensions?

A: Always list them as Length × Width × Height.

Q: Should I use internal or external measurements?

A: Use internal for product fit, external for shipping or stacking.

Q: Do I need special tools?

A: No—just a ruler or measuring tape. For accuracy, measure twice.

🎯 Final Thoughts

Accurately measuring your custom packaging box saves time, reduces errors, and ensures a better fit for your products. Clear dimensions help your supplier deliver high-quality results, whether you’re ordering 100 or 10,000 boxes.