I. Introduction: The Future of Alcohol Packaging

The global alcohol industry is entering a new era in 2025 — one defined by premiumization, sustainability, and experience. Consumers are no longer purchasing beverages solely for taste; they are investing in the story, craftsmanship, and emotion behind each bottle. As the market for high-end wines and spirits continues to expand, luxury packaging has become a silent ambassador of brand value.

For brand owners, importers, and distributors, packaging plays a pivotal role in shaping first impressions and communicating quality before the bottle is even opened. A sophisticated alcohol gift box does more than protect — it elevates the product, enhances brand storytelling, and builds trust among consumers.

However, as aesthetics advance, safety remains the cornerstone of effective packaging. A truly premium box must balance visual appeal with engineered protection, ensuring that every glass bottle arrives intact, regardless of distance or handling. In 2025, the most successful packaging solutions are those that combine elegance, functionality, and sustainability into a seamless experience.

II. Key Considerations in Modern Alcohol Gift Box Design

Designing premium packaging for alcohol requires far more than creativity. It’s a process that blends structural engineering, materials science, and brand strategy. Below are the fundamental aspects shaping today’s most successful alcohol gift boxes:

1. Structural Integrity

A luxury alcohol box begins with structure. The rigidity and precision of construction determine not only aesthetics but also how well the product withstands transportation.

- Rigid board thickness typically ranges from 1000gsm to 1500gsm for durability.

- Reinforced corners and double-wall panels protect against compression and impact.

- Magnetic or hinged closures ensure a secure yet elegant opening experience.

2. Custom-Fitted Inserts

No two bottles are alike. The insert — whether EVA foam, molded pulp, or die-cut cardboard — must be custom-engineered to fit the exact bottle dimensions.

- This prevents movement, absorbs shock, and protects the neck and base from pressure.

- Velvet, fabric, or paper linings add both cushioning and a sense of refinement.

3. Material Sustainability

Today’s consumers expect luxury to be responsible. Brands are increasingly choosing FSC-certified rigid boards, soy-based inks, and biodegradable foams to align with sustainable values.

- Eco-conscious packaging enhances brand reputation while meeting import compliance standards in global markets.

4. Aesthetic and Tactile Experience

Visuals matter, but so does the feel. Textured papers, foil stamping, embossing, and soft-touch lamination combine to create an immersive sensory experience.

- These techniques allow a brand to convey personality — minimalistic, traditional, or artistic — without compromising on structural reliability.

5. User Experience and Unboxing

In the luxury segment, the unboxing process is part of the product value. Drawer slides, flip-top lids, and magnetic closures provide both functionality and anticipation.

- Each motion — from the lift of the lid to the reveal of the bottle — should feel deliberate, smooth, and rewarding.

- Precision engineering ensures that even the smallest design detail enhances both safety and elegance.

III. How Packaging Protects the Bottle and Enhances Value

Behind every beautiful box is a foundation of precision engineering designed to safeguard delicate glass bottles. The success of luxury packaging lies in how effectively it combines protection, presentation, and performance.

1. Engineering Meets Design

While design attracts the eye, structural integrity preserves the value. Premium boxes are built from high-density rigid board and layered internal reinforcements that provide compression resistance and durability.

- The outer shell absorbs external stress, while the internal insert locks the bottle firmly in place.

- Even minor details — such as corner folding and glue placement — affect the overall stability during transport.

2. Precision Testing and Quality Control

High-end packaging is tested for drop resistance, vibration stability, and humidity exposure to ensure global shipping reliability.

- Manufacturers often simulate shipping conditions to confirm that bottles remain secure and labels undamaged.

- These tests reinforce confidence for exporters, especially in fragile products like champagne, cognac, and aged whiskey.

3. Adaptive Inserts for Maximum Security

Well-designed inserts are customized to the bottle’s contour. EVA foam, molded pulp, or corrugated spacers are strategically positioned to absorb shock and prevent friction.

- Inserts should always match the exact height, width, and curvature of the bottle to prevent internal movement.

- For premium presentation, the insert can be covered with satin or specialty paper for a refined look.

4. Safe and Sustainable Materials

Rigid boxes now integrate eco-safe cushioning materials — recyclable paper trays, biodegradable foams, and compostable dividers — reducing environmental impact while maintaining protection.

- This balance between safety and sustainability defines the future of luxury packaging.

5. The Emotional and Commercial Value of Safety

Safety is not just a technical specification; it’s a signal of reliability. When customers receive a perfectly protected bottle, they associate it with care, professionalism, and trust.

- For business owners, this translates into fewer damages, stronger customer loyalty, and higher perceived value.

IV. The Top 6 Luxury Alcohol Gift Box Designs for 2025

In 2025, premium alcohol packaging continues to evolve toward a balance of elegance, functionality, and protection. Each box design type serves a unique role — from enhancing presentation to ensuring bottle stability during storage and transport. Below are six representative structures widely favored in the global premium wine and spirits market.

1. Handle Gift Box Design

Structure:

A portable rigid box with a built-in rope or paper handle, designed for easy carrying and gifting. The magnetic or flip-top lid opens to reveal a well-organized bottle display.

Printing & Finish:

Full-color offset printing with playful graphics, matte lamination, and selective spot UV detailing enhance brand visibility.

Material:

Made from 1000–1200gsm rigid cardboard wrapped in coated paper for strength and a refined finish.

Trend Insight:

Consumers appreciate packaging that combines practicality and visual appeal. This box type supports both retail and gifting scenarios, reflecting a “functional luxury” approach.

Safety Feature:

Custom-cut EVA or molded pulp inserts are crucial — precisely shaped to match the bottles, keeping them upright and preventing collision during transport.

Usage Recommendation:

Perfect for retail promotions, travel sets, or multi-bottle gift assortments.

2. Drawer Gift Box Design

Structure:

A sliding drawer box that reveals the bottle through a pull-out motion, enhancing the unboxing experience. The outer sleeve wraps securely around the inner tray.

Printing & Finish:

Elegant matte surfaces combined with foil stamping or embossed metallic accents create a luxurious texture.

Material:

High-density rigid board (1200gsm) offers durability and weight, while velvet or paper-wrapped inner trays reinforce quality perception.

Trend Insight:

Drawer boxes are increasingly used for limited editions and collector’s packaging, allowing for both reusability and presentation value.

Safety Feature:

The inner tray includes precisely molded foam cavities that cradle the bottle’s shape, minimizing lateral movement. Velvet-lined interiors add friction and extra cushioning.

Usage Recommendation:

Ideal for single high-value bottles or limited-release collections.

3. Flip-Top Box Design

Structure:

A classic one-piece rigid box with a hinged lid that opens upward in a clean, seamless motion. The elegant geometry creates a refined silhouette that highlights simplicity and precision craftsmanship.

Printing & Finish:

Minimalist black or neutral color palettes are often enhanced with gold or silver foil stamping, subtle embossing, or soft matte lamination to convey timeless sophistication.

Material:

Made from rigid paperboard (up to 1500gsm), wrapped in premium specialty paper for a solid structure and smooth, tactile finish. The interior can be lined with velvet, textured paper, or gold foil paper to elevate the unboxing experience.

Trend Insight:

Flip-top boxes are a long-standing favorite in the world of corporate gifting and premium alcohol packaging. Their simple, structured form reflects modern elegance while keeping focus on the product itself.

Safety Feature:

The lid’s hinged design ensures easy opening while maintaining stability. Inside, custom-cut EVA foam or molded pulp inserts hold the bottle securely in place. The insert should match the bottle’s shape precisely, supporting the neck, body, and base to prevent any movement or damage.

Usage Recommendation:

Best suited for executive gifts, high-end spirits, or export-grade single-bottle packaging where visual balance, structure, and safety are equally important.

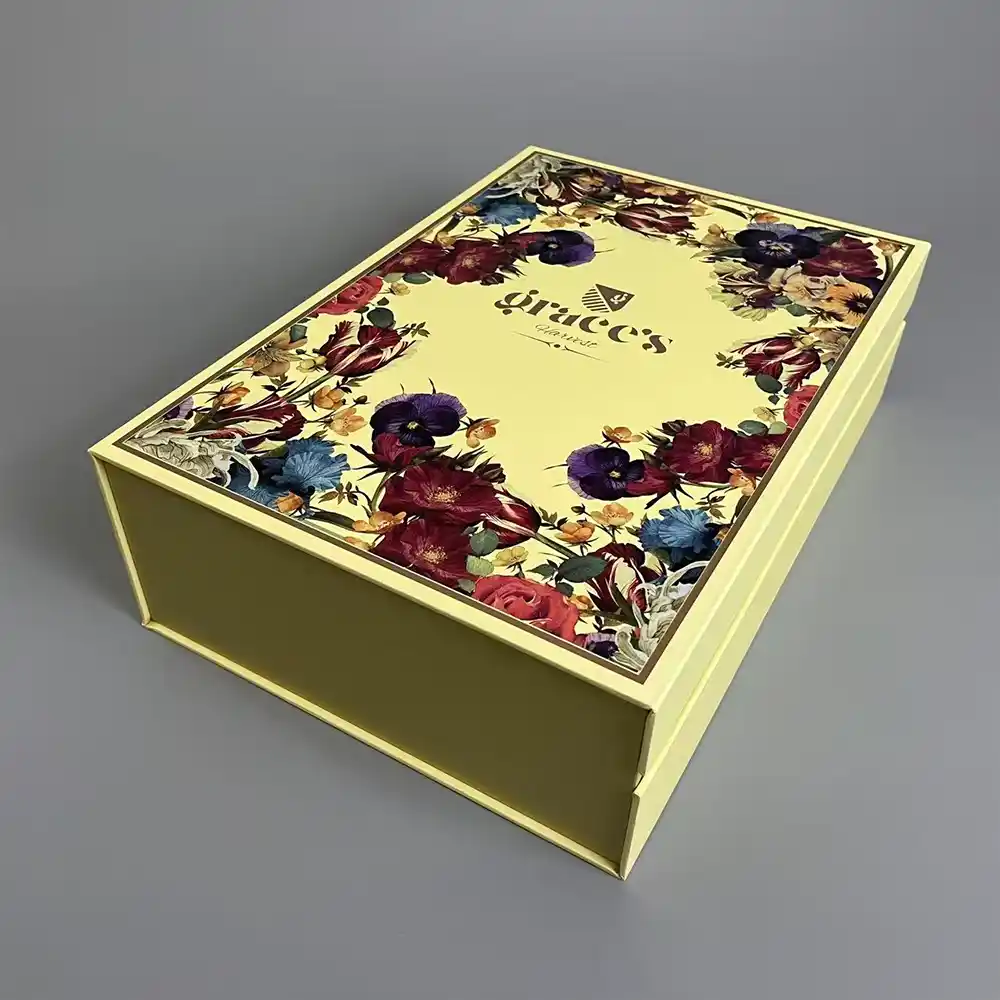

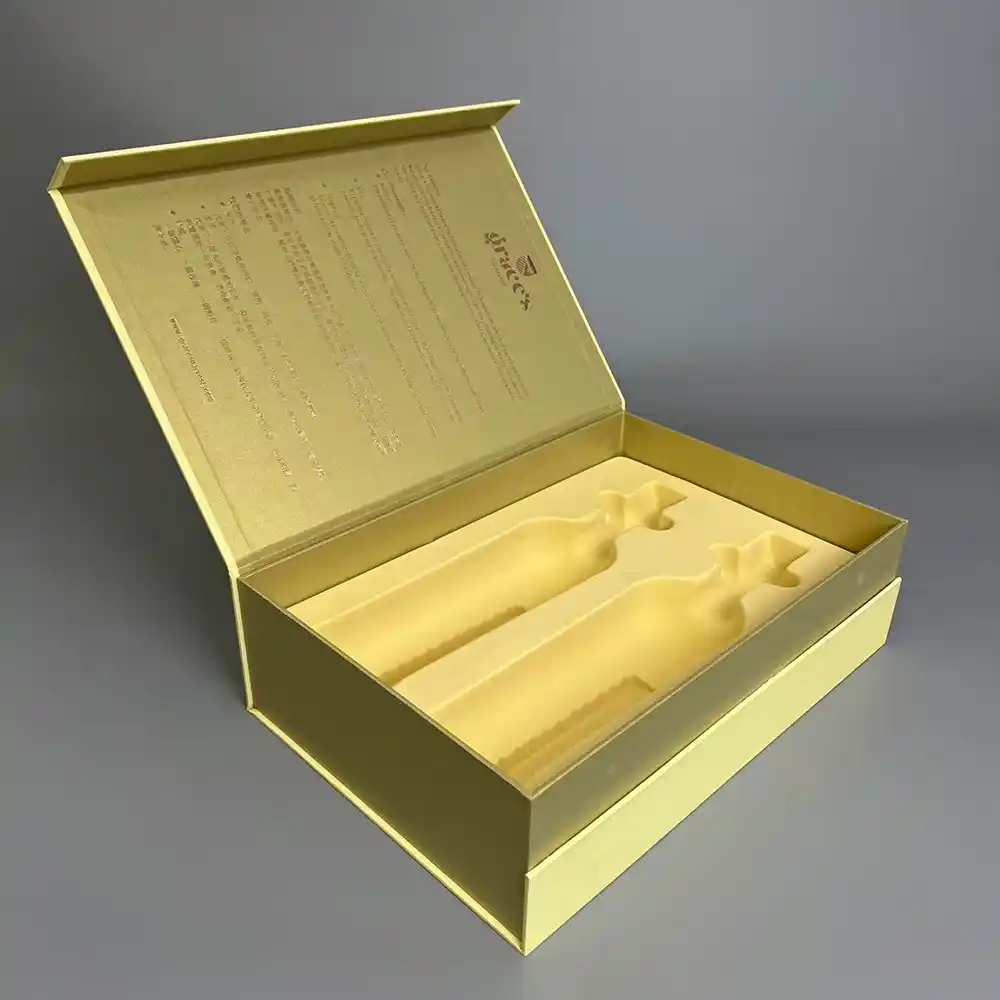

4. Magnetic Lid Gift Box with Decorative Printing

Structure:

A rigid box with a hinged magnetic lid and full-depth interior tray. This structure offers both strong protection and a generous printable surface.

Printing & Finish:

High-resolution full-color printing, floral or artistic patterns, and soft matte lamination provide a rich tactile and visual impression.

Material:

Eco-paper or art paper laminated over grayboard; interior trays can be molded paper pulp or colored EVA.

Trend Insight:

This design reflects a fusion of art and craftsmanship — appealing to lifestyle-oriented brands that value both aesthetics and sustainability.

Safety Feature:

Soft molded inserts protect bottles from vibration while maintaining precise alignment. A double-wall base adds compression resistance.

Usage Recommendation:

Suitable for wine gift sets, dessert wines, or lifestyle beverage brands targeting elegant retail display.

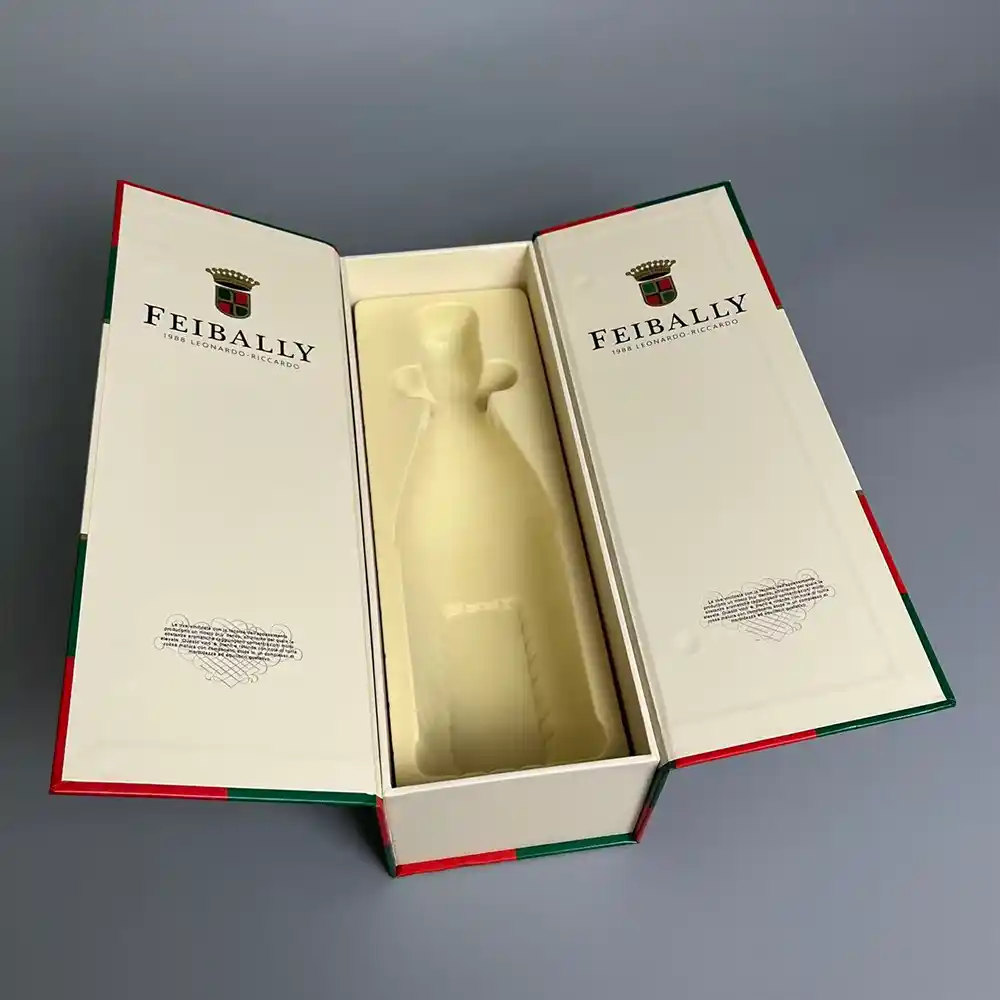

5. Modern Double-Door Magnetic Box Design

Structure:

This packaging adopts a dual-door magnetic design that opens symmetrically from the center, presenting a refined and modern aesthetic. The geometric structure creates a visual balance, while the concealed magnets ensure smooth closure and secure sealing.

Printing & Finish:

The minimalist exterior often features soft neutral tones such as beige, ivory, or charcoal black. Micro-embossed textures or matte lamination elevate the surface tactility, while a small, centered label or metallic logo plate adds a focal point of sophistication.

Material:

Constructed with 1200gsm rigid board, wrapped in specialty paper for structural firmness and surface refinement. The interior is lined with contrasting dark tones to highlight the clean, architectural look.

Trend Insight:

This design reflects the global trend of “modern soft luxury” — favoring simplicity, geometry, and calm colors that appeal to both genders and diverse age groups.

Safety Feature:

Inside, custom EVA foam inserts are precisely cut to fit each bottle’s contour, securing both neck and base. The triangular flaps on both sides reinforce the structure, preventing compression and maintaining perfect symmetry even after repeated use.

Usage Recommendation:

Ideal for boutique wineries, craft spirit brands, or gift collections emphasizing elegance and modernity. It’s particularly suitable for e-commerce or long-distance shipment thanks to its excellent stability and internal support system.

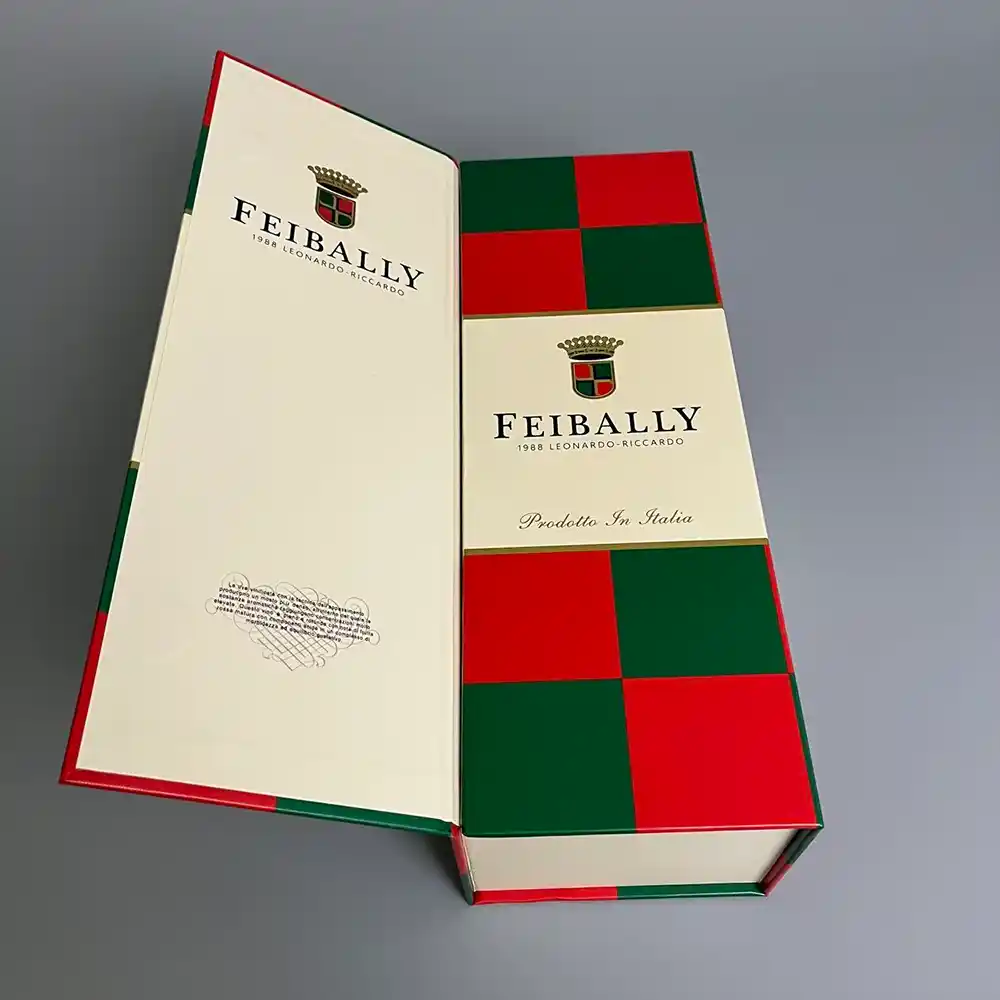

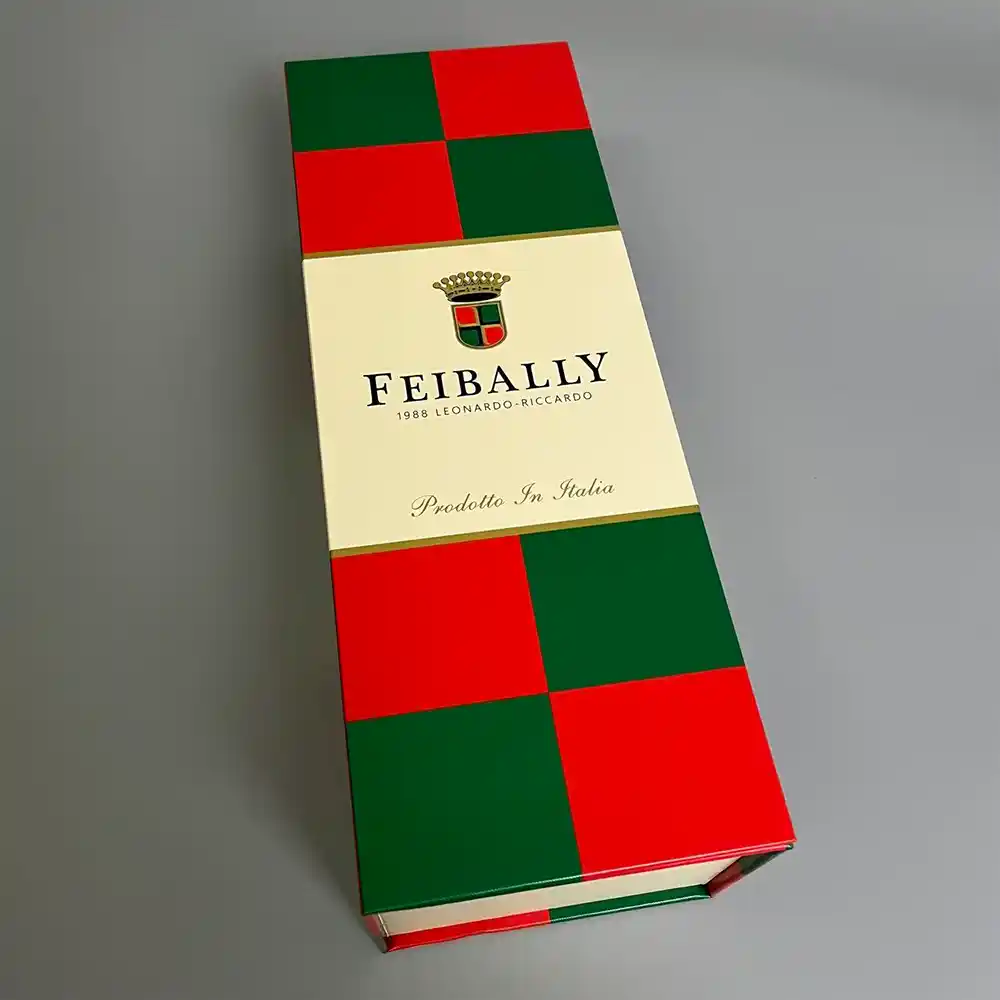

6. Hinged Double-Door Gift Box Design

Structure:

This is a high-end dual-hinged rigid box that opens outward like a pair of grand doors, symbolizing ceremony and exclusivity. The strong magnetic closure ensures secure transport, while the hinged construction provides smooth and balanced opening.

Printing & Finish:

The surface design typically combines matte lamination with rich colors such as ivory, emerald green, or deep red. Subtle foil stamping, embossing, or UV coating are used to highlight key elements — blending modern elegance with a touch of classic charm.

Material:

Built with thick grayboard (up to 1400gsm) for excellent rigidity and durability. Inside, a custom molded insert — made from EVA foam or biodegradable pulp — holds the bottle firmly in place. The dual-door structure is supported by strong spine hinges to prevent deformation.

Trend Insight:

This packaging design represents heritage luxury — blending European-inspired aesthetics with contemporary engineering. It’s a favorite among brands seeking to express craftsmanship, history, and authenticity.

Safety Feature:

Every insert is precision-engineered to match the actual bottle shape, ensuring the neck, shoulders, and base are fully supported. The double-door structure distributes force evenly, minimizing impact during handling or shipping. For export packaging, this model meets both aesthetic and safety standards, ensuring premium protection for fragile glass bottles.

Usage Recommendation:

Best suited for high-value or collectible bottles — such as aged wines, limited-edition spirits, or commemorative releases — where presentation and preservation are equally important.

Ideal for premium spirits, collectible bottles, and export-grade packaging requiring both visual prestige and high-level protection.

Each of these six packaging structures showcases how modern luxury packaging integrates protection, sustainability, and storytelling. The key to success lies not only in how the box looks but also in how it performs — ensuring that every bottle arrives as beautifully as it was designed.

V. Design Innovation Trends for 2025

As consumer expectations evolve, packaging innovation in the alcohol industry has shifted toward sustainability, personalization, and intelligent engineering. The year 2025 marks a convergence of artistry and technology — where every design decision balances aesthetics, performance, and environmental responsibility.

1. Sustainability & Eco-Materials

Sustainability has become the new benchmark for luxury. Modern alcohol packaging increasingly uses FSC-certified paper, recyclable rigid boards, biodegradable inserts, and soy-based inks.

- Molded pulp and paper foam inserts are replacing plastic trays, offering protection with minimal environmental impact.

- Many brands now design multi-use boxes that customers can repurpose for storage, extending both brand exposure and product lifespan.

2. Smart Packaging Technology

Smart elements such as QR codes, NFC chips, or RFID tags are being integrated into luxury alcohol boxes to connect the physical product with digital storytelling.

- Consumers can scan packaging to verify authenticity, learn about origin, or access tasting notes and pairing ideas.

- For premium exporters, smart packaging also supports supply chain tracking and anti-counterfeit protection.

3. Surface Finishing & Tactile Enhancement

In luxury packaging, touch is as important as sight.

- Advanced finishing methods — such as hot foil stamping, 3D embossing, soft-touch lamination, and digital spot varnish — create an emotional connection through texture.

- Minimalist design with one or two premium finishes can achieve more impact than overly complex visuals, aligning with global “quiet luxury” aesthetics.

4. Structural Engineering & Safety Testing

The fusion of design and engineering ensures that beauty never compromises protection.

- Drop testing, compression resistance, and vibration simulation are now standard for export packaging.

- Structural engineers focus on optimizing board thickness, hinge strength, and insert density to achieve zero-damage delivery.

- Protective innovation is also driving material research — lightweight yet impact-resistant paperboard is a key trend in 2025.

5. Personalization & Small-Batch Customization

As gifting culture expands, brands increasingly demand low MOQ custom packaging to serve niche collections, private labels, or seasonal releases.

- Short-run digital printing and modular box design make small-batch production both cost-effective and sustainable.

- This flexibility allows even emerging wineries and craft distillers to create high-end experiences without large inventories.

VI. Strategic Insights for Business Owners

For brand owners and decision-makers in the wine and spirits industry, packaging strategy is now directly tied to market positioning and consumer loyalty.

1. Packaging as a Brand Investment

High-quality packaging is not a cost center — it’s an investment in brand equity. Premium boxes elevate perception, justify higher price points, and create long-term differentiation in saturated markets.

2. Balancing Cost and Performance

The key to successful packaging lies in smart material selection — achieving strength and visual impact without unnecessary expense.

- Using rigid paperboard instead of wood, or paper foam instead of plastic, balances durability with sustainability.

3. Custom Fit = Product Safety

Every bottle design is unique; therefore, one-size-fits-all inserts should be avoided. A custom-fitted insert not only prevents movement but also enhances perceived quality.

- Working with an experienced packaging manufacturer ensures that insert design, material density, and bottle dimensions are perfectly matched.

4. Sustainability as a Competitive Advantage

Consumers and importers are actively choosing eco-conscious brands. By adopting recyclable and biodegradable materials, businesses align with modern environmental standards while enhancing export potential.

5. Storytelling Through Design

Each box should communicate the brand’s personality — from minimal modern lines to classic European elegance.

- The integration of tactile finishes, intelligent inserts, and sustainable choices tells a story of care and precision that resonates with both retail and online buyers.

VII. Conclusion: Protecting Value, Elevating Experience

Luxury alcohol packaging in 2025 represents more than aesthetic refinement — it is a statement of craftsmanship, responsibility, and protection.

Every element, from structural integrity to printing finesse, reflects a brand’s values and respect for the product inside.

A well-designed alcohol gift box does three things exceptionally well:

- Protects the bottle with precision engineering and tailored inserts.

- Communicates luxury through refined materials and finishing.

- Connects the consumer emotionally to the brand experience.

As global demand for premium beverages grows, packaging innovation will continue to define the line between ordinary and extraordinary. For modern brands, the future of alcohol packaging lies in one philosophy — design with purpose, protect with precision, and present with passion.