1. Introduction

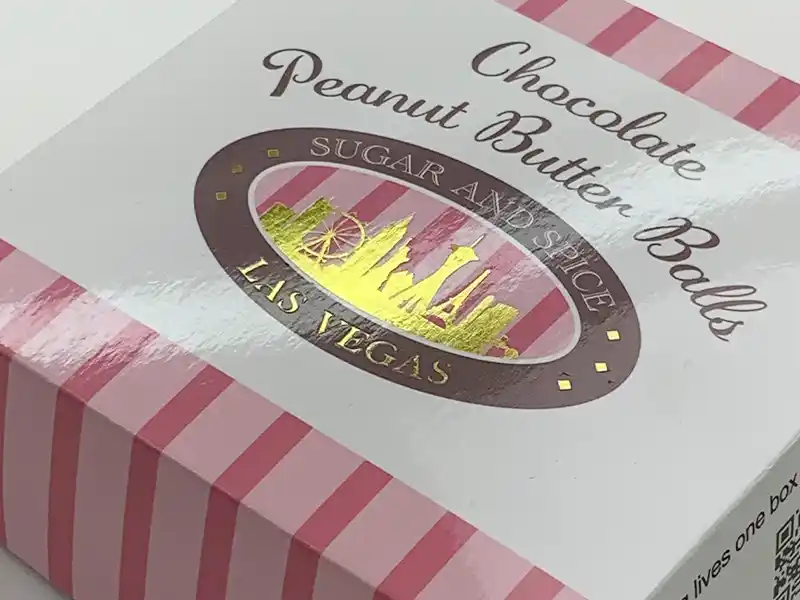

Have you ever picked up a product and noticed a shiny, metallic logo that instantly gave it a premium feel? That’s likely the result of hot stamping, a printing technique often used in packaging to create elegant, eye-catching details. Whether it’s gold accents on a luxury box or a holographic logo on a gift bag, hot stamping plays a big role in how brands stand out.

This guide will walk you through the basics of hot stamping—what it is, how it works, and why it’s a go-to choice for upscale packaging and printing. If you’re new to the world of print finishes, you’re in the right place.

2. What Is Foil Stamping?

Hot stamping, also commonly known as foil stamping, is a printing method that uses heat, pressure, and metallic or pigmented foil to transfer a design onto a surface. Unlike ink-based printing, foil stamping doesn’t use liquid. Instead, it applies a thin layer of foil film to the substrate—typically paper, cardboard, or plastic—through a heated metal die.

The result? A striking, often metallic, finish that gives packaging a tactile and visual edge. While it’s most often seen in gold or silver, foil stamping comes in many styles—from matte colors to holographic effects.

Key characteristics:

- No ink involved—foil film is applied with heat.

- Commonly used to highlight logos, borders, or product names.

- Works best on smooth, flat surfaces.

3. Types of Foils Used in Stamping

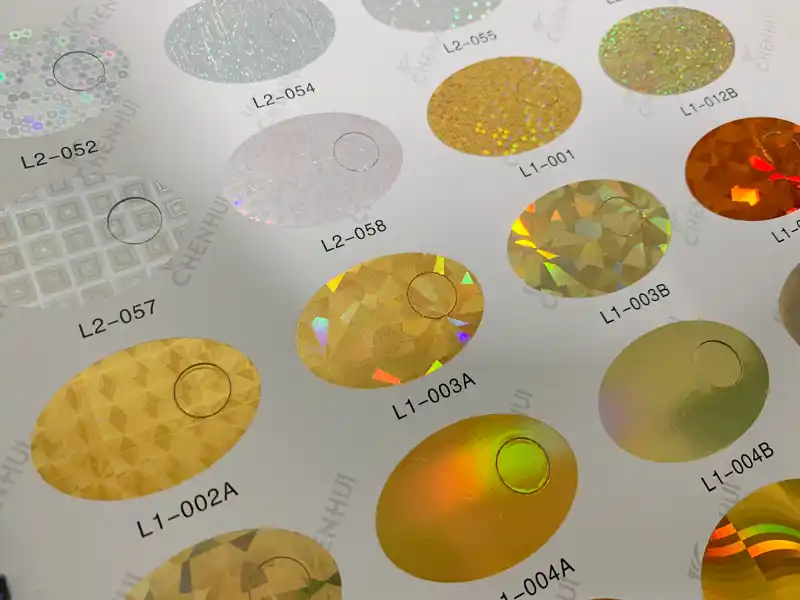

Hot stamping isn’t one-size-fits-all. There are different types of foil available, each offering a unique look and feel. Here are the most common ones:

🔸 Metallic Foils

These are the most popular and recognizable types—think gold, silver, rose gold, or copper. Metallic foils reflect light and create a luxurious, high-end appearance. Ideal for premium packaging and branding.

🔸 Pigment Foils

These foils don’t shine but come in solid colors like black, white, red, or blue. They’re great when you want a bold yet flat (non-reflective) look.

🔸 Holographic Foils

This type creates a rainbow effect that shifts with the light. It’s often used in tech products, cosmetics, or anything aiming for a futuristic or playful vibe.

🔸 Transparent & Clear Foils

Used when a glossy or matte overlay is needed without color. These foils add texture or finish without altering the color underneath.

Each foil type can drastically change how your final product looks and feels. That’s why foil selection is a key part of packaging design.

4. How the Foil Stamping Process Works

Hot stamping may sound complex, but the process is fairly straightforward. Here’s a simple breakdown of how it works:

🔹 Step 1: Design Preparation

First, the desired artwork (such as a logo or brand name) is finalized and converted into a custom metal die—this die acts like a stamp.

🔹 Step 2: Die Creation

The metal die is etched with your design and will be heated during the stamping process.

🔹 Step 3: Foil Selection

Based on your design goals, a suitable foil (metallic, pigment, or holographic) is chosen. The foil is loaded into the hot stamping machine.

🔹 Step 4: Stamping

Using heat and pressure, the die presses the foil onto the packaging surface. The heat activates the adhesive layer on the foil, causing it to bond with the material.

The result is a crisp, shiny (or matte) design that stands out—literally and visually.

Materials Compatible with Hot Stamping:

- Coated and uncoated paper

- Cardboard

- Kraft board

- Rigid boxes

- Plastic films (in limited cases)

The process is valued not only for its beauty but also for its durability. Foil stamping doesn’t smudge or fade as easily as ink, making it ideal for long-lasting impressions.

5. Advantages of Hot Stamping in Packaging

So, why do so many brands choose hot stamping for their packaging? Here are the main benefits that make it worth the investment:

✅ Premium Visual Appeal

Nothing catches the eye like a metallic or holographic highlight. Hot stamping gives your packaging a polished, upscale look that instantly boosts perceived product value.

✅ Tactile Experience

When combined with embossing or used on textured materials, hot stamping adds a physical element that customers can feel—enhancing engagement and brand recall.

✅ Versatile Design Options

From bold metallic finishes to subtle matte foils, hot stamping works across a range of styles. It’s adaptable for seasonal, promotional, or luxury packaging needs.

✅ Durability

Foil finishes are more resistant to smudging, fading, or wear compared to traditional inks—especially useful for products with a longer shelf life.

✅ Eco-Friendly Potential

When applied to recyclable paperboard or cardboard, hot stamping can be part of a sustainable packaging strategy. Foil coverage is minimal and often doesn’t hinder recyclability.

6. Bonus: Hot Stamping Often Pairs with Embossing

In many premium packaging designs, hot stamping is frequently combined with embossing—a technique that raises the surface of the material to create a three-dimensional effect. When used together, the result is both visually striking and physically tactile.

For example, a gold foil-stamped logo that’s also embossed will catch the light and stand out to the touch, giving customers a richer, more interactive experience. This combination is commonly used on:

Rigid gift boxes

Jewelry packaging

High-end cosmetic cartons

Premium greeting cards

If you’re aiming for a truly elevated packaging experience, pairing hot stamping with embossing is a popular and effective design choice.

7. Common Misconceptions about Hot Stamping

Despite its popularity, a few myths still surround hot stamping. Let’s clear them up:

❌ “Hot stamping is only for gold or silver.”

Not true. While metallic foils are popular, you can also choose from colored pigments, holographic effects, and even transparent finishes.

❌ “It’s too expensive for small businesses.”

Hot stamping has become more accessible in recent years. While there are setup costs (like die production), short-run options and digital foil alternatives can make it cost-effective.

❌ “It’s not sustainable.”

Foil stamping can be eco-conscious when applied thoughtfully. The amount of foil used is minimal and doesn’t necessarily affect recyclability when applied to recyclable paper.

❌ “Foil always looks flashy.”

Foil can be subtle, too. Matte foils and clear finishes are perfect for brands looking for sophistication without excessive shine.

8. Conclusion

Hot stamping is more than just a decorative touch—it’s a proven way to enhance the visual impact, tactile feel, and perceived value of packaging. Whether you’re designing for cosmetics, tech, or gourmet products, this finishing technique helps your brand stand out in a competitive market.

From luxurious metallics to modern matte foils, the options are endless—and so are the opportunities to make your packaging unforgettable.