1. Introduction

Packaging does more than just protect what’s inside. Today, it’s a vital part of how products are presented, shipped, and even remembered. From enhancing the unboxing experience to reinforcing your brand image and keeping shipping costs down, the right packaging can make a big difference.

But not every product fits the same box. Choosing the right packaging box style depends on a few key factors—like the product’s size, weight, fragility, and even your marketing goals. Whether you’re sending a fragile item across the country or preparing a luxury gift set, the type of box you choose matters.

In this guide, we’ll walk through 12 commonly used packaging box types, with a clear look at their structure and the materials typically used. Whether you’re new to custom packaging or want to refine your current solution, this breakdown will help you make the right call.

Keywords included naturally: packaging box styles, common packaging box types.

2. Overview of Common Packaging Materials

Not all boxes are created equal—and much of that comes down to the material they’re made from. Understanding the three main types—paper, cardboard, and corrugated—is key to choosing the right packaging solution for your product.

2.1 Paper

(SBS C2S, Brown Kraft Paper, Black Kraft Paper, White Kraft Paper, Gold/Silver/Holographic Paper, Specialty Paper)

Common Grammage: 180–400gsm

Paper packaging is lightweight, flexible, and excellent for printing. It’s also more environmentally friendly than many plastic-based options, making it a popular choice for brands focusing on sustainability.

This material is ideal for smaller or lightweight products, especially when presentation matters. Its clean surface supports high-quality printing, foil stamping, and custom finishes.

Common Uses: Pillow boxes, display boxes, custom printed retail packaging.

2.2 Cardboard

(Grey Chipboard, Duplex Chipboard)

Common Grammage: 800–1400gsm

Cardboard—also known as paperboard or chipboard—offers a rigid, high-end feel, perfect for premium or gift-style packaging. It’s sturdier than paper but still customizable in shape, size, and finish.

It provides excellent support for heavier items and works well with magnetic closures, inserts, and layered designs.

Common Uses: Magnetic boxes, drawer boxes, lid and base boxes, rigid gift boxes.

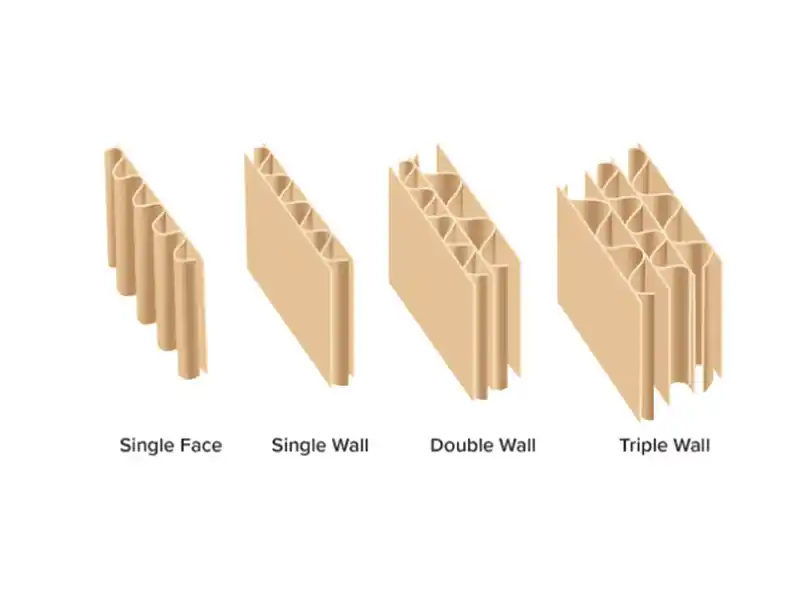

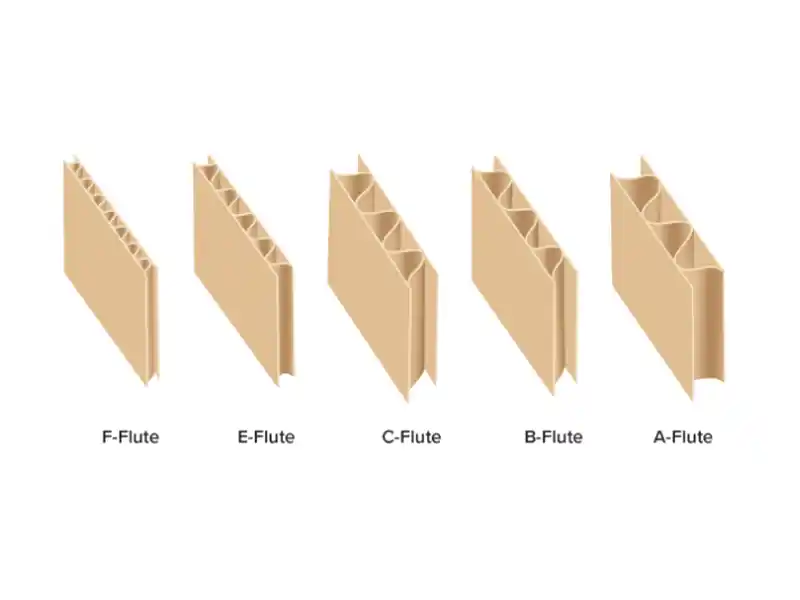

2.3 Corrugated Paper

(Brown Kraft Corrugated, White Kraft Corrugated, Black Kraft Corrugated)

Flute Types: A, B, C, E, F

Structures: Single Face, Single Wall, Double Wall, Triple Wall

Corrugated packaging is all about strength and durability. Built from fluted inner layers between linerboards, it’s designed to protect products during shipping or storage.

The flute type (A, B, C, E, F) determines the box’s thickness and cushioning ability. Heavier or fragile items benefit from thicker flutes like C or B, while E and F are great for lighter, more compact packaging.

Common Uses: Mailer boxes, shipping cartons, heavy-duty packaging, subscription boxes.

3. 12 Common Packaging Box Types

Each type of packaging box serves a specific purpose, offering different levels of protection, presentation, and user experience. Below, we break down 12 of the most commonly used box styles, along with their structures, suitable materials, and typical applications.

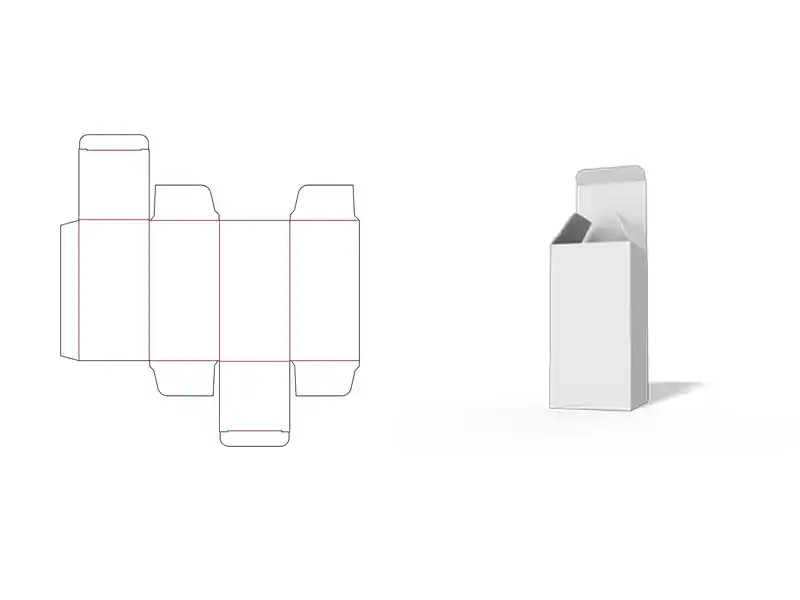

3.1 Straight Tuck End Box (STE)

A simple yet functional structure, the straight tuck end box features tuck flaps on both the top and bottom that fold in the same direction. It assembles easily and maintains a clean, professional look with no raw edges showing on the front.

- Materials: Paper or Corrugated Paper

- Best For: Cosmetics, small electronics, retail packaging

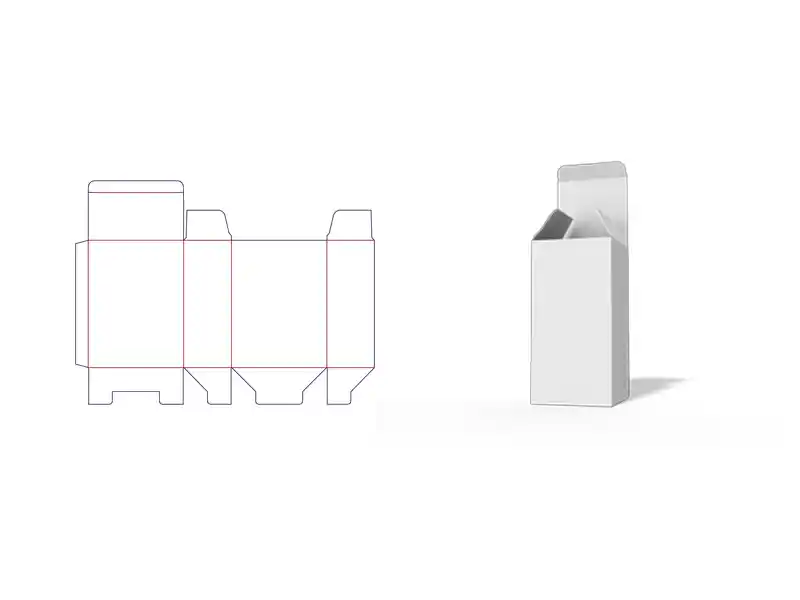

3.2 Auto Bottom Box (Tuck End with Auto-Lock Bottom)

This box features a folding structure that automatically locks into place without the need for glue. The bottom is designed to interlock when opened, offering quick assembly and secure support—especially useful for speeding up the packing process.

- Materials: Paper or Corrugated Paper

- Best For: Lightweight electronics, snacks, bakery products

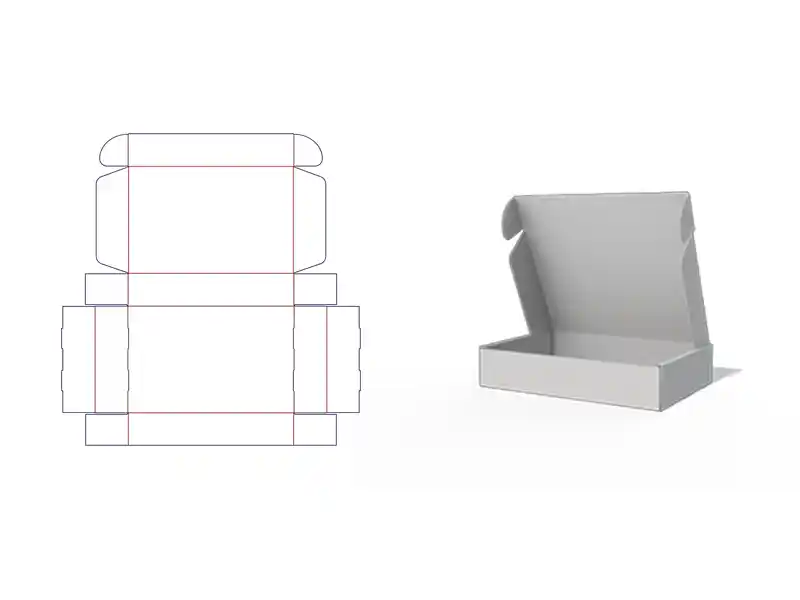

3.3 Mailer Box

Known for its self-locking flaps and strong sidewalls, the mailer box is ideal for both shipping and presentation. It opens like a gift box and doesn’t require additional adhesives.

- Materials: Corrugated Paper or thick Paper

- Best For: E-commerce packaging, subscription boxes, promotional kits

3.4 Shipping Box (Regular Slotted Carton – RSC)

Designed for maximum durability, shipping boxes have high load-bearing capacity and are often used for bulk shipments. Flaps meet in the center when closed.

- Materials: Corrugated Paper

- Best For: Appliances, wholesale goods, warehouse logistics

3.5 Magnetic Closure Box

This premium box style features hidden magnets in the flap, delivering a smooth and luxurious unboxing experience. The rigid structure supports custom inserts and decorative finishes.

- Materials: Hard Cardboard

- Best For: Gift packaging, luxury items, corporate kits

3.6 Lid and Base Box (Two-Piece Box)

Also called a rigid setup box, this two-piece structure includes a detachable lid and a base. It’s commonly used for elegant packaging and provides good protection with high-end appeal.

- Materials: Hard Cardboard or Paper

- Best For: Shoes, jewelry, apparel sets

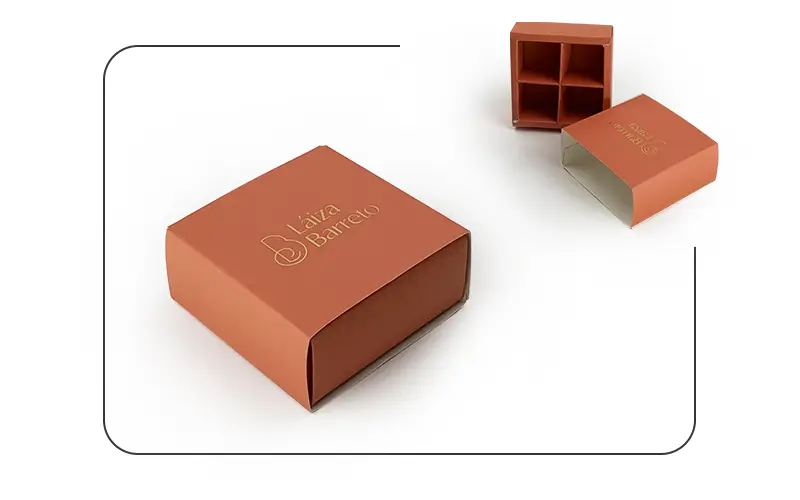

3.7 Drawer Box (Slide-Out Box)

Resembling a matchbox, the drawer box includes a sleeve and a sliding tray. It’s functional and visually refined, often paired with ribbons or thumb notches for easy access.

- Materials: Hard Cardboard or Paper

- Best For: Accessories, fashion packaging, tech gadgets

3.8 Display Box

Built with a fold-out window or die-cut panel, the display box is designed to showcase products directly on shelves. It’s usually used as secondary packaging and is often recyclable.

- Materials: Paper, Cardboard, or Corrugated Paper

- Best For: Point-of-purchase (POP) displays, trial-size items, counter sales

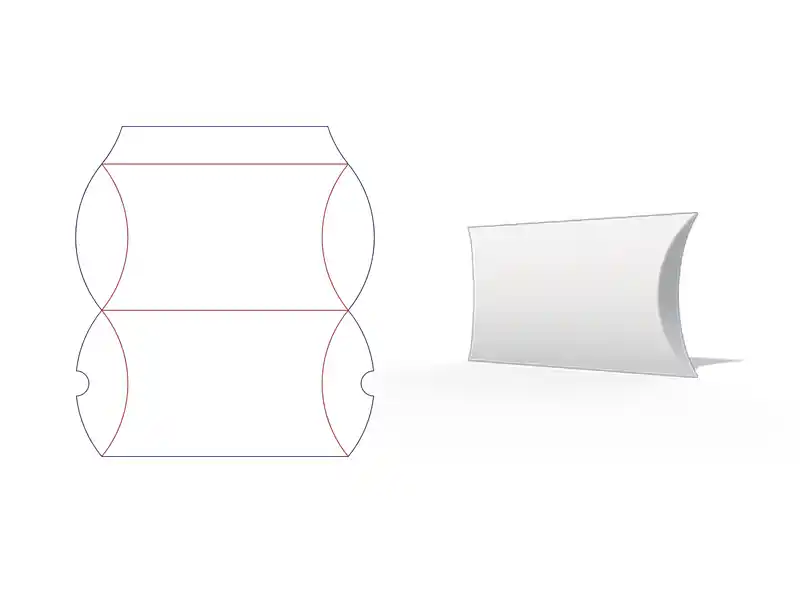

3.9 Pillow Box

This curved, foldable box features tuck-in flaps at both ends. Despite its soft appearance, it can hold lightweight products securely and is great for branding.

- Materials: Paper

- Best For: Gift cards, handmade soaps, cosmetics

3.10 Hinged Lid Box

The lid is attached to the base with a spine-like fold, opening like a book or jewelry box. Its structure supports strong rigidity and premium finishes.

- Materials: Hard Cardboard

- Best For: Tools, small electronics, keepsake boxes

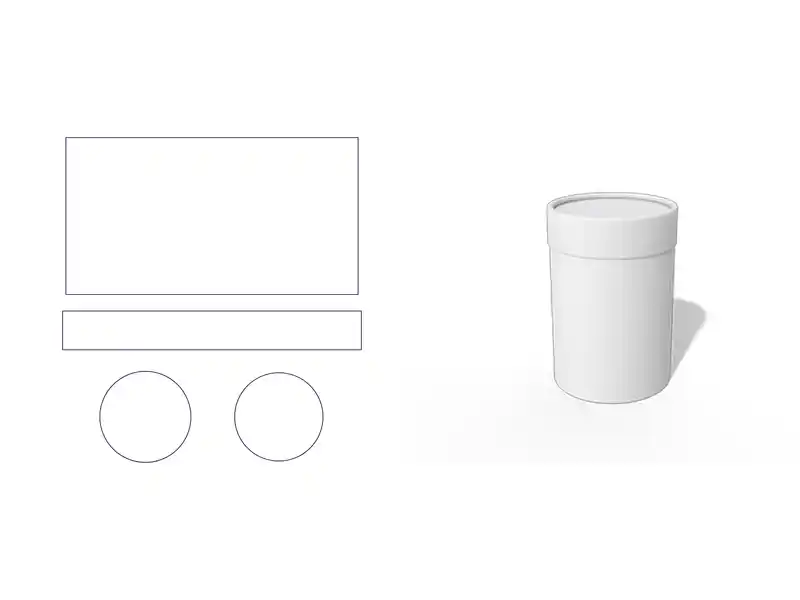

3.11 Round Box (Tube Box)

A cylindrical box that stands out from standard square or rectangular shapes. Often wrapped in printed paper or specialty finishes for visual impact.

- Materials: Kraft Paper, Cardboard, or premium Paper

- Best For: Candles, tea, cosmetics, gourmet foods

3.12 Polygon Box

Uniquely shaped (hexagonal, octagonal, etc.), this box breaks the mold for traditional packaging. Its geometry catches attention and elevates the unboxing moment.

- Materials: Cardboard / Corrugated

- Best For: High-end gifts, promotional packaging, souvenir items

🔎 Quick Summary Table (Optional for SEO/UX)

| Box Type | Material | Common Use Cases |

|---|---|---|

| Straight Tuck End | Paper / Corrugated | Retail, Cosmetics |

| Auto Bottom | Paper / Corrugated | Food, Electronics |

| Mailer Box | Corrugated / Paper | E-commerce, Subscriptions |

| Shipping Carton | Corrugated | Bulk Shipping, Logistics |

| Magnetic Box | Hard Cardboard | Luxury Packaging |

| Lid & Base Box | Cardboard / Paper | Apparel, Jewelry |

| Drawer Box | Cardboard / Paper | Fashion, Accessories |

| Display Box | Paper / Cardboard | Retail Displays |

| Pillow Box | Paper | Gifts, Small Items |

| Hinged Lid Box | Hard Cardboard | Tools, Collectibles |

| Round Box | Kraft / Cardboard / Paper | Candles, Tea, Cosmetics |

| Polygon Box | Cardboard / Corrugated | High-End Branding |

4. How to Choose the Right Packaging Box for Your Product

With so many box styles and materials available, how do you know which one is right for your product? The best choice depends on a combination of product characteristics, branding goals, and shipping requirements. Here’s a quick breakdown of what to consider:

✅ 1. Product Weight and Fragility

- Lightweight or delicate items: Consider paper-based boxes like pillow boxes or tuck end boxes with inserts.

- Heavier items: Choose corrugated boxes (e.g., mailers or shipping cartons) with appropriate flute strength (e.g., C-flute or double wall).

✅ 2. Desired Unboxing Experience

- Want to impress customers with a premium reveal? Go with a magnetic box or drawer box for a high-end feel.

- For basic retail or utility, straight tuck end or auto-lock bottom boxes get the job done without unnecessary cost.

✅ 3. Shipping or In-Store Display?

- For e-commerce and shipping, durability is key. Use mailer boxes or shipping cartons made of corrugated material.

- For retail shelves, visual appeal matters. Boxes like display boxes or lid-and-base boxes help products stand out.

✅ 4. Sustainability Goals

If eco-friendliness is part of your brand promise, opt for kraft paper, recyclable cardboard, or minimalist folding designs that reduce waste and shipping volume.

✅ 5. Branding & Customization Needs

Some box styles offer more flexibility for printing, embossing, foil stamping, or adding custom inserts. Cardboard boxes like magnetic or drawer styles are perfect for luxury branding, while paper boxes offer cost-effective customization for everyday items.

Pro Tip: Before committing to large-scale production, request samples or mockups to evaluate the look, feel, and strength of the box under real-world conditions.

5. Conclusion

Packaging isn’t just a container—it’s part of your product’s story. Choosing the right box style and material ensures that your product is protected, presented professionally, and aligned with your brand values.

Whether you’re shipping nationwide, launching a luxury item, or preparing for retail display, there’s a packaging solution that fits your needs. By understanding the different box types and materials, you’re better equipped to make smart, cost-effective packaging decisions that enhance the customer experience.

🔄 Bonus: Frequently Asked Questions (FAQ)

Q1: What is the difference between cardboard and corrugated boxes?

A: Cardboard (also called paperboard) is a single, thick paper-based material best for premium packaging. Corrugated boxes have a fluted inner layer for added strength, ideal for shipping or heavier products.

Q2: Which box is best for e-commerce packaging?

A: Mailer boxes made of corrugated paper are the most popular choice—they’re sturdy, self-locking, and look great on delivery.

Q3: Can I print custom designs on all box types?

A: Yes, but some materials (like coated paper or SBS) offer better results for high-quality printing, foil stamping, or embossing.

Need Expert Advice on Packaging?

If you have questions about packaging or need guidance choosing the right box, feel free to contact us here.

Some images in this article are sourced from Pacdora and PakFactory for illustrative purposes.