1. Introduction

For small and medium-sized businesses, choosing the right printing method is one of the most important decisions when ordering custom packaging. Whether you’re launching a new product, running a seasonal promotion, or simply need a short run of branded boxes, understanding the differences between digital printing and offset printing can help you control costs, improve color consistency, and avoid overordering.

While digital printing is known for its flexibility and speed, offset printing offers superior color reproduction and long-term value—especially as quantities increase. But which option makes the most sense for small custom packaging runs?

Let’s break down the advantages and limitations of each printing method and explore why 300 pieces is often the tipping point where the balance shifts.

2. Digital Printing (Best for 1–300 pcs)

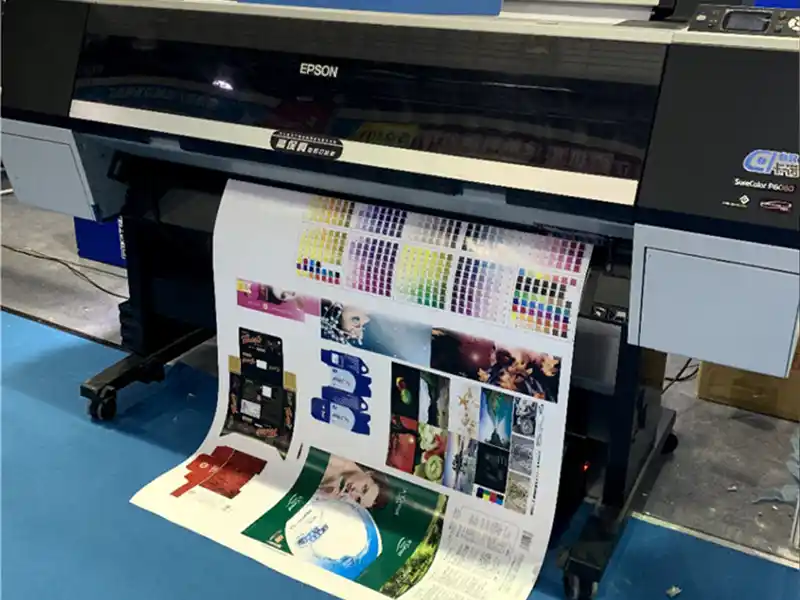

Digital printing uses inkjet or laser technology to print directly onto packaging material, without the need for plates or setup time. This makes it a great option for low-quantity orders, especially when you need samples, personalized packaging, or quick turnaround.

✅ Advantages:

- Low minimum order quantity (MOQ): Print as few as 1–100 pieces

- No setup costs: Ideal for test runs or small batches

- Faster production time: Shorter lead times than offset printing

- Flexible for design changes: Easy to modify SKUs, artwork, or messaging

⚠️ Limitations:

- CMYK-only color system: Cannot reproduce exact Pantone colors

- Slight color variation: May not match perfectly across batches

- Higher unit cost at scale: Becomes less economical beyond 300–500 pcs

Digital printing is best suited for startups, seasonal editions, and packaging prototypes where speed and flexibility matter more than perfect color consistency.

3. Offset Printing (Recommended for 300+ pcs)

Offset printing involves creating printing plates and transferring ink onto the packaging through a rubber blanket. Though setup takes longer, offset printing is widely used for professional, large-scale packaging thanks to its color accuracy and production efficiency.

Traditionally, offset printing becomes cost-effective at 1,000+ pieces, as the upfront cost of plate-making and machine calibration is distributed over a larger quantity. However, based on our experience, we’ve found that 300 units is often the point where offset printing begins to offer similar costs to digital printing—with better print quality.

✅ Advantages:

- Superior color reproduction: Supports Pantone and exact color matching

- Consistent results: Ensures brand consistency across batches

- Lower unit cost at volume: Economies of scale kick in after setup

⚠️ Limitations:

- Higher setup cost: Not ideal for very small runs

- Longer lead time: Requires more time for setup and production

- Less flexible: Design changes mean starting the setup process over

For brands that care deeply about visual consistency—especially with color-sensitive packaging like cosmetics or gourmet foods—offset printing is the more reliable choice. Even if you’re ordering 300 units, the improved print quality and color stability can make a big difference in customer perception.

4. Cost and Efficiency Breakdown

When choosing between digital and offset printing, cost efficiency often comes down to quantity. Here’s a breakdown of how the two compare across common production factors:

| Factor | Digital Printing | Offset Printing |

|---|---|---|

| MOQ | 1–300 pcs | 300 pcs and above |

| Setup Cost | None | Moderate (plate + setup required) |

| Unit Cost (Small Run) | Higher | Slightly higher at 300 pcs, then drops |

| Unit Cost (Large Run) | Higher | Much lower at 1000+ pcs |

| Turnaround Time | Fast (2–5 days) | Slower (5–10+ days) |

| Color Quality | CMYK only | CMYK + Pantone support |

| Consistency | Minor batch variation | High color and print consistency |

Key Insight:

Offset printing becomes cost-efficient as quantity increases due to the way setup costs are spread out. At around 300 pcs, the total cost of offset printing starts to converge with digital printing. At that point, offset offers better print quality without significantly increasing your expenses.

For brands planning to reorder packaging or maintain visual consistency across campaigns, offset is often worth the extra 1–2 days of lead time.

5. Real-World Scenarios: When to Use Each Method

Let’s explore how different business types approach printing decisions based on their needs:

🧴 Example 1: A Skincare Startup

Launching a new product line for a limited seasonal promotion? Digital printing allows you to print just 50–200 boxes quickly, without committing to a large inventory. It’s perfect for testing new designs, scents, or formulations.

🍫 Example 2: Artisanal Chocolate Brand

After successful testing, the brand begins regular production. Now needing 500–1,000 boxes per month, they shift to offset printing. This ensures brand consistency, vibrant Pantone colors, and lower unit costs in the long run.

🧪 Example 3: Product Sampling Campaign

A supplement company preparing for a trade show only needs 80 boxes. They choose digital printing to create high-quality, branded packaging in under a week, with the flexibility to change designs later based on feedback.

6. Choosing the Right Method for Your Order

Here’s how to decide:

Choose Digital Printing If:

- You’re ordering under 300 pcs

- You need quick delivery or a sample run

- Your design includes many variations or SKUs

- Color matching is not critical

Choose Offset Printing If:

- Your order is 300 pcs or more

- You require precise color consistency

- You plan to reorder in the future

- Your packaging will be displayed on shelves

👉 Tip: If you’re on the fence, ask your supplier for samples of both methods to see the difference in finish and feel.

7. Final Thoughts

There’s no one-size-fits-all answer when it comes to printing methods for custom packaging. Digital printing is ideal for speed, flexibility, and small test runs. Offset printing, on the other hand, shines in color precision and long-term cost efficiency, especially at quantities over 300 pieces.

By understanding the strengths and trade-offs of each method—and matching them to your project’s volume, timeline, and branding needs—you can make a smarter choice that aligns with your packaging goals and budget.