Introduction: Why Waterproof Packaging Matters

In the world of custom packaging, functionality matters just as much as design. Whether you’re packaging food, cosmetics, electronics, or retail products, one question often comes up: Is the packaging waterproof?

To protect packaging from moisture, grease, and everyday handling, two common surface finishing processes are widely used — lamination and oil coating (also called varnishing). Both offer varying degrees of waterproofing and durability, but they differ in performance, finish, and cost.

Here’s what you need to know before choosing the right method for your packaging.

What Is Lamination?

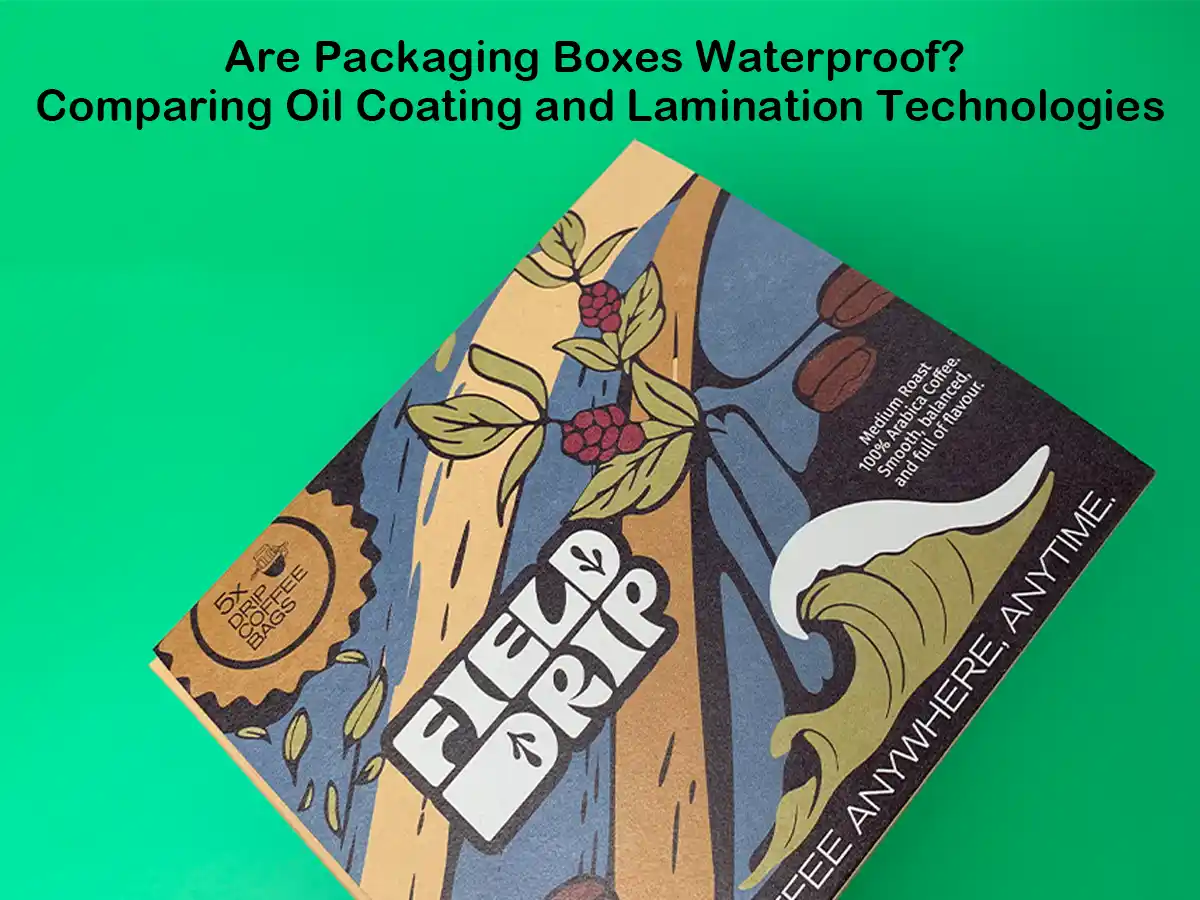

Lamination is a finishing technique where a thin, transparent plastic film is applied to the surface of printed materials using heat and pressure. This layer protects the print, enhances color, and adds a professional finish.

There are two main types of lamination:

- Glossy Lamination – Creates a shiny, reflective surface that makes colors more vibrant.

- Matte Lamination – Offers a soft, non-reflective finish that feels more premium but slightly mutes color contrast.

Common laminated packaging products include:

- Gift boxes and folding cartons

- Branded shopping bags

- Seed bags and agricultural packaging

- Labels and stickers

Matte lamination is particularly popular for upscale packaging thanks to its soft texture and modern look. However, it can reduce color brightness slightly compared to gloss lamination.

What Is Oil Coating (Varnishing)?

Oil coating, also referred to as varnishing, is a process that applies a thin, liquid coating — either glossy or matte — directly onto printed paper. Unlike lamination, it doesn’t use plastic film. It enhances the surface appearance and provides basic resistance against water, oil, and scratches.

Two main types of varnishes are commonly used:

- Gloss Varnish – Adds a shiny finish that enhances color vibrancy.

- Matte Varnish – Offers a more subdued, elegant look with a smoother feel.

Oil coating is often preferred when the packaging uses specialty paper with a unique texture. Lamination can cover up that texture, but varnish preserves it while still offering surface protection.

Waterproofing: Lamination vs. Oil Coating

Both lamination and oil coating provide a level of waterproofing, but their effectiveness varies.

| Feature | Lamination | Oil Coating (Varnish) |

|---|---|---|

| Water Resistance | ✅ Excellent – Can be rinsed or wiped | ☑️ Moderate – Light wiping only |

| Durability | ✅ High – Scratch and tear resistant | ☑️ Medium – Prone to wear over time |

| Finish Options | Glossy / Matte | Glossy / Matte |

| Specialty Paper Use | ❌ Not suitable – masks paper texture | ✅ Compatible – maintains texture |

| Cost | Slightly higher | Lower cost |

Durability & Appearance:

Laminated packaging is more durable overall. It withstands friction and handling well, and can be wiped or even rinsed without damage. Oil-coated packaging is more delicate — over-wiping can cause ink to fade or the surface to scratch.

Finish & Paper Compatibility:

Both techniques allow for glossy or matte effects. However, lamination is not recommended for specialty paper (like embossed or textured paper), as it hides the paper’s tactile feel. In such cases, varnishing is the better choice.

Cost Consideration:

While lamination is slightly more expensive than varnishing, the price difference is generally small and depends on quantity and packaging type.

When Should You Use Each?

Choose Lamination if:

- You need high water or oil resistance

- The packaging is for high-touch or high-moisture environments

- A sleek, professional look is preferred

Choose Oil Coating if:

- You’re using specialty paper and want to preserve texture

- Budget is limited

- You need basic protection with a natural or artistic finish

For instance, a luxury skincare box might benefit from matte lamination for both durability and elegance, while handmade soap packaging might use kraft paper with a matte varnish to keep the natural feel visible.

Conclusion: Which Waterproofing Option Is Better?

So, are packaging boxes waterproof? They can be — if finished correctly.

- Lamination offers superior protection and durability, making it ideal for retail, food, and cosmetic packaging where appearance and resilience matter.

- Oil coating provides a more delicate, cost-effective solution, ideal for textured paper or short-term packaging needs.

Ultimately, the best choice depends on your material, usage, design goals, and budget. Understanding the strengths of both processes can help you make smarter decisions when customizing your packaging.