When it comes to custom paper packaging, lamination isn’t just a finishing touch — it’s a decision that directly affects the look, feel, and durability of your product box. Whether you’re launching a luxury skincare line or shipping tech accessories, selecting the right lamination can help elevate your brand and protect your packaging at the same time.

In this guide, we’ll break down the most common lamination types — from standard glossy and matte finishes to advanced options like scratch-resistant and soft-touch films — so you can choose the one that fits your product and customer expectations best.

What Is Lamination in Paper Packaging?

Lamination is the process of applying a thin plastic film over the printed surface of a paper box to enhance its visual appeal and strengthen its durability. This added layer acts as a protective barrier, guarding against scratches, moisture, fingerprints, and wear from handling or transport.

For packaging manufacturers and brand owners alike, lamination offers an easy way to upgrade both the aesthetic and functional quality of paper boxes without changing the structural design.

Common Lamination Types for Paper Boxes

1. Matte Lamination

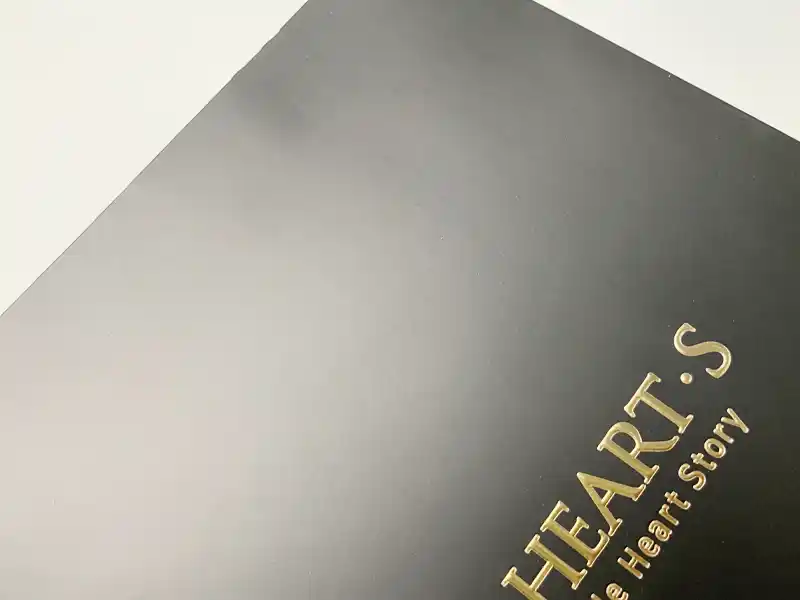

Matte lamination gives packaging a soft, velvety texture with a muted, non-reflective finish. It’s ideal for brands that want to convey sophistication, minimalism, or a natural tone.

Key Features:

- Smooth and understated finish

- Reduces glare under lighting

- Tends to resist fingerprints better than glossy finishes

Best Used For:

- Luxury gift boxes

- High-end cosmetic or skincare packaging

- Brands with subtle, elegant color palettes

Keep in Mind:

While matte lamination adds an upscale look, it may show scratches more easily over time than other finishes unless paired with scratch-resistant technology.

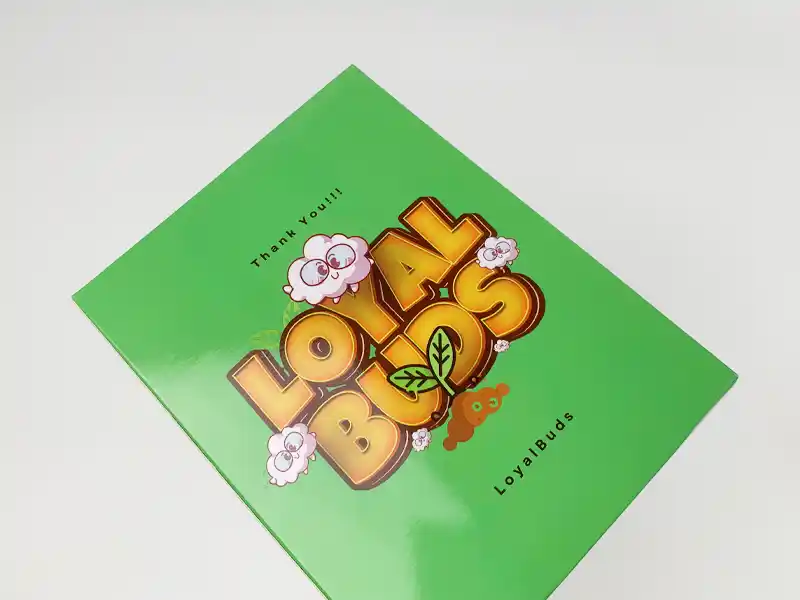

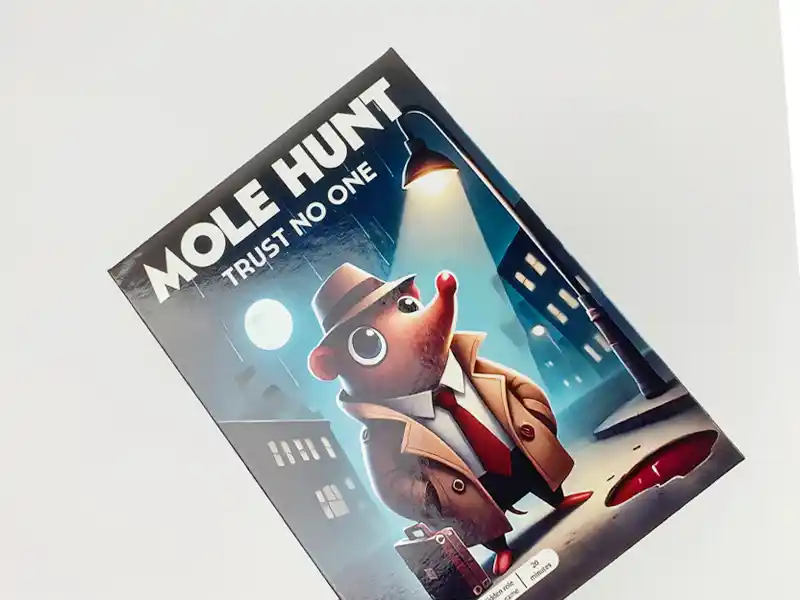

2. Glossy Lamination

Glossy lamination is one of the most widely used finishes in commercial paper box production. It adds a shiny, reflective surface that enhances color vibrancy and gives packaging a bold, eye-catching appearance.

Key Features:

- Bright, reflective surface

- Enhances color contrast and sharpness

- Economical and widely available

Best Used For:

- Retail display packaging

- Food and beverage cartons

- Boxes with detailed illustrations or photography

Keep in Mind:

Glossy lamination is visually appealing but can show fingerprints or smudges more easily, especially in darker color schemes.

Advanced Functional Laminations

While matte and glossy laminations are popular for their aesthetic value, more brands today are opting for functional films that provide added protection or tactile experiences.

1. Scratch-Resistant Lamination

Scratch-resistant film is designed to maintain the pristine look of the packaging even under heavy handling. It’s available in both matte and glossy variants and is particularly useful for boxes that are frequently touched, stacked, or transported.

Key Features:

- Extra durability against surface damage

- Ideal for e-commerce or retail environments

- Preserves premium look over time

Best Used For:

- Electronics packaging

- Hardcover book slipcases

- Product boxes in high-traffic retail stores

Use Case Insight:

A brand selling wireless earbuds might use matte scratch-resistant film to preserve the sleek look while ensuring the box doesn’t scuff easily in-store displays.

🧠 Design Tip:

Dark-colored packaging — particularly black — is more likely to show scratches and scuffs. For this reason, scratch-resistant lamination is often recommended when using black or other deep hues in your box design. It ensures the surface stays sharp and unblemished, even with heavy handling.

2. Touch-Sensitive (Soft-Touch) Lamination

Soft-touch film — sometimes called velvet or suede lamination — gives the surface a smooth, rubbery, or velvet-like feel. It’s designed to create a tactile experience that appeals to touch, offering a sense of exclusivity.

Key Features:

- Rich, velvety feel

- Fingerprint-resistant

- Communicates premium branding

Best Used For:

- Luxury product boxes

- Boutique cosmetics

- Limited-edition or promotional packaging

Use Case Insight:

A perfume brand may use soft-touch lamination to align the packaging experience with the sensual, high-end feel of the product inside.

How to Choose the Right Lamination for Your Paper Box

Choosing the right lamination isn’t just about looks. It’s about aligning the function, cost, and brand message of your packaging. Here are a few key factors to guide your decision:

✅ 1. Product Type

- Fragile items like glass bottles may benefit from tougher finishes like scratch-resistant film.

- Gifting products or luxury cosmetics may lean toward matte or soft-touch laminations.

✅ 2. Branding Goals

- Want bold and vibrant? Go glossy.

- Looking for minimalist and high-end? Matte or soft-touch may be more appropriate.

✅ 3. Handling & Durability

- Packaging that’s handled often (e.g., in retail or shipping) needs finishes that resist scuffing or damage.

- Consider scratch-resistant films if your boxes will be on shelves for extended periods.

✅ 4. Budget Considerations

- Standard matte and glossy films are cost-effective and widely available.

- Advanced films (scratch-resistant, soft-touch) cost more but add functional or emotional value that may justify the investment.

✅ 5. Design Compatibility

- Glossy lamination enhances contrast and brightness — great for bold graphics.

- Matte and soft-touch work best with subdued color palettes and minimalist designs.

Final Thoughts

Lamination plays a powerful role in shaping both the look and durability of your packaging. It’s more than just a protective layer — it’s a branding tool. Whether you opt for the shine of glossy film, the elegance of matte, or the tactile luxury of soft-touch, your choice should align with your product’s identity and your customers’ expectations.

If you’re unsure which lamination best suits your paper box, working closely with your packaging manufacturer can help you weigh the pros and cons based on your specific needs. Lamination may seem like a small detail, but the right choice can make a big difference in how your packaging is perceived — and how well it performs.