Introduction

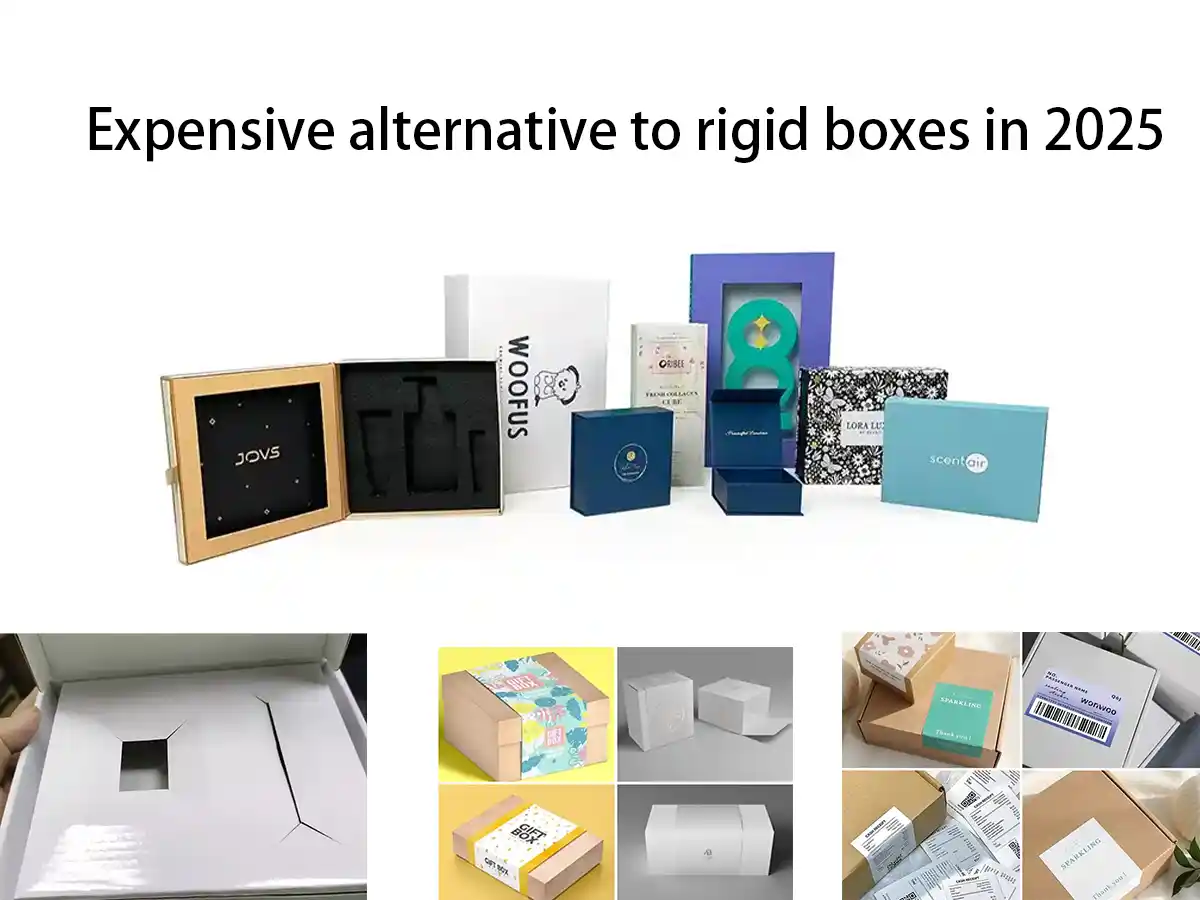

Rigid boxes—also known as set-up boxes—are often associated with luxury and quality. From high-end electronics to premium cosmetics, they’ve long been the go-to option for brands seeking a premium presentation. Their structure is strong, their surfaces are smooth and printable, and their visual appeal is undeniable.

But with all that elegance comes a price.

For many businesses, especially those managing product variety, frequent launches, or tight margins, rigid boxes present challenges beyond just unit cost. They’re heavy, non-collapsible, and expensive to ship and store. In an increasingly competitive market, brands are now exploring packaging alternatives that maintain a premium feel—without the high costs that rigid boxes often demand.

In this article, we’ll break down exactly why rigid boxes are expensive, and then introduce five practical, cost-effective alternatives that still offer durability, customization, and aesthetic value.

1. Why Are Rigid Boxes So Expensive?

While rigid boxes certainly deliver on visual and tactile quality, there are several hidden costs that drive up their price. Here are the key reasons why rigid boxes are often the most expensive custom packaging option:

1.1 Material Costs

Rigid boxes are typically made using thick chipboard (also called greyboard or paperboard), which provides structural strength. This board is then wrapped with printed or textured specialty paper, often laminated or coated for a smooth finish. Both the board and the wrapping material add to the overall cost, especially when compared to lighter materials like corrugated board or folding carton stock.

For premium brands, the wrapping paper may include specialty textures, embossing, foil, or varnish—all of which increase material expenses.

1.2 Labor-Intensive Production

Unlike folding cartons or corrugated mailers that are often machine-formed, rigid boxes require more manual labor. Processes like gluing, folding, and wrapping are time-consuming and often completed by hand or semi-automated machines.

The added complexity means longer lead times, higher labor costs, and limited flexibility for small-batch or fast-turnaround production.

1.3 High Shipping Costs

Rigid boxes are typically non-collapsible. This means they take up significantly more space during transit compared to flat-packed packaging types. The result is higher shipping volume (known as dimensional weight), which translates to more expensive freight—especially for overseas shipments or bulk orders.

In logistics, size matters as much as weight. Rigid boxes often require palletizing or specialized cartons, driving up costs.

1.4 Inefficient Storage

Because they cannot be flattened, rigid boxes also take up more space in your warehouse or fulfillment center. This storage inefficiency leads to increased warehousing costs—especially for brands with high SKU counts or seasonal products that don’t move quickly.

The more space your packaging takes up before it’s even filled, the more overhead it creates.

1.5 Limited Scalability and Customization Flexibility

Rigid box production is not ideal for businesses that need quick adjustments or small batches. Each size or structure change usually requires a new tooling or die, which can be cost-prohibitive. This makes rigid boxes better suited for long-term, high-volume products—less so for evolving product lines or e-commerce testing.

2. 5 Hard Box Alternatives

Rigid boxes offer premium quality—but they’re not the only way to deliver a memorable unboxing experience. The following five alternatives provide flexibility, protection, and branding potential, all at a lower cost. These options can be tailored to fit your product’s needs, whether you’re shipping direct-to-consumer or stocking retail shelves.

Alternative #1 – Corrugated Boxes

Corrugated packaging is a classic choice that’s both durable and affordable. Thanks to its fluted inner structure, it provides excellent protection for shipping, even for fragile or heavy items.

Why It Works

Corrugated boxes are widely used for secondary packaging, but with the right design and materials, they can also take on a premium appearance.

Customization Tips

- Use micro-flutes (F-flute or N-flute): These provide a smoother surface for printing and greater rigidity—ideal for consumer-facing packaging.

- Choose white or coated linerboard: This enhances print quality and brand visibility.

- High-end finishes: Add matte or gloss lamination, soft-touch coating, or spot UV to elevate the look.

- Add structure: Custom die-cuts, paper inserts, or compartments improve both presentation and product protection.

🟢 Best For: Electronics, cosmetics, e-commerce kits, luxury food packaging.

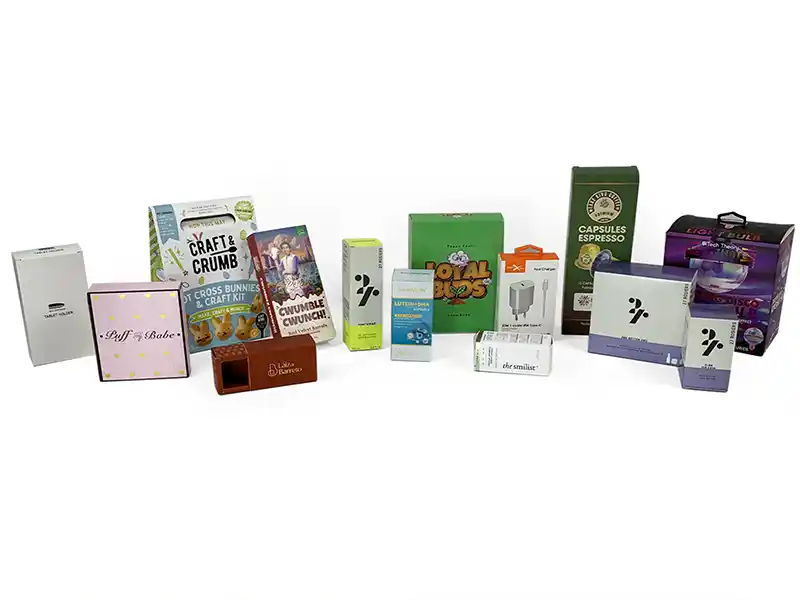

Alternative #2 – Folding Cartons

Folding cartons are lightweight, print-friendly, and ship flat—making them a popular option for consumer goods.

Why It Works

These boxes are made from paperboard (typically 14pt–28pt) and can be produced quickly and efficiently at scale. Their smooth surfaces allow for high-quality printing, and they’re easy to customize with structural variations.

Design Recommendations

- Reinforced box styles: Use snap-lock bottom or crash-bottom styles for added support.

- Double-wall construction: Folding thicker stock or layering board increases strength and adds a more rigid-like appearance.

- Visual enhancements: Add foil stamping, embossing, or soft-touch lamination for a tactile, premium feel.

🟢 Best For: Lightweight products such as skincare, accessories, supplements, or retail display packaging.

Alternative #3 – Sleeve Packaging

Sleeve packaging offers minimalism with maximum impact. It’s a low-material, high-design approach that turns simple boxes into premium-looking packages.

Why It Works

By wrapping a custom-printed sleeve around a plain inner box, brands can create a sophisticated visual presentation without the cost of a fully custom rigid box.

Applications & Finishing

- Paired with folding cartons or trays: A sleeve can be used to differentiate product lines or seasonal collections.

- Custom finishes: Add spot UV, die-cut windows, or textured paper for luxury appeal.

- Sustainability bonus: Less material means lower environmental impact and cost.

🟢 Best For: Gift sets, subscription boxes, promotional items, cosmetic packaging.

Alternative #4 – Sticker + Universal Packaging

This approach uses generic or standardized boxes paired with custom labels or stickers to create a branded experience. It’s ideal for fast-growing brands or companies with large product variations.

Why It Works

Instead of producing a different box for every SKU, brands can simplify their packaging inventory and use stickers to identify or personalize each product.

How to Execute

- Start with blank kraft or white mailer boxes.

- Add custom-designed labels or logo stickers.

- Enhance with tissue wrap, branded tape, or printed cards.

- Use belly bands or stamps for added branding.

🟢 Best For: Startups, handmade products, short runs, or e-commerce packaging that needs flexibility and fast turnaround.

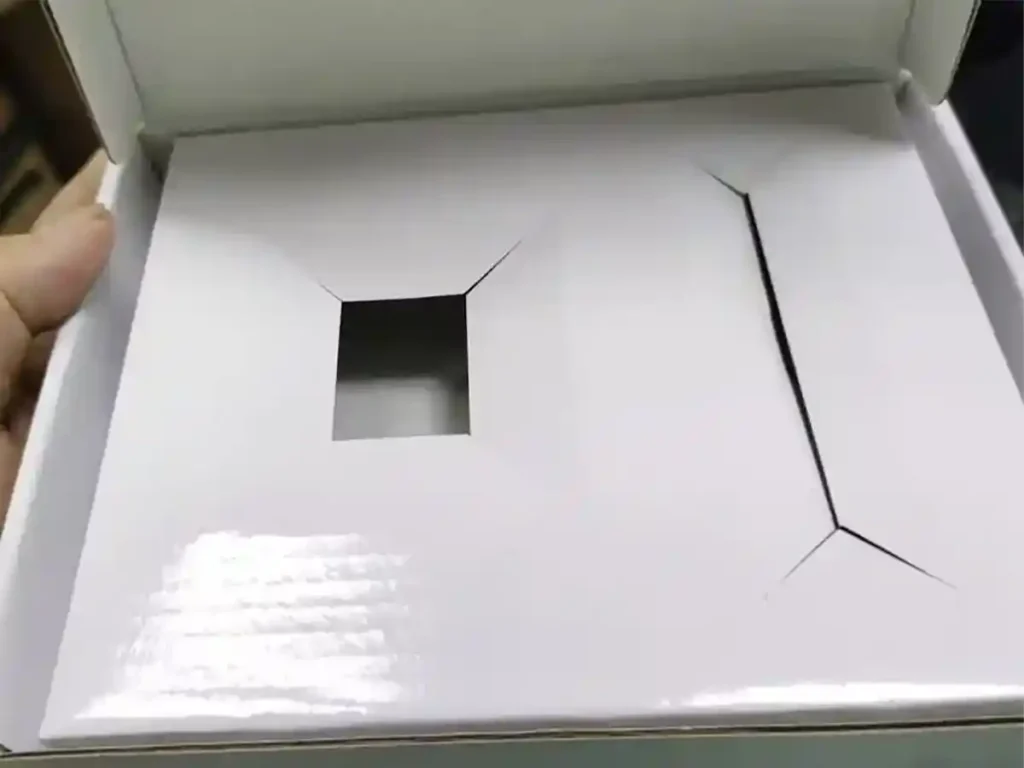

Alternative #5 – Hybrid Packaging (Mix & Match)

Hybrid packaging combines different materials or box styles to strike a balance between cost-efficiency and visual appeal. It’s a creative way to incorporate premium touches without committing to full rigid box production.

Why It Works

By selectively mixing elements—such as using a rigid lid with a corrugated base or combining folding cartons with foam inserts—brands can get the feel of luxury at a lower cost.

Creative Combinations

- Corrugated tray with a printed sleeve

- Folding carton with molded pulp or foam insert

- Magnetic flap made from high-grade paperboard instead of chipboard

🟢 Best For: Premium gift boxes, electronics, high-value kits, or items that need structured internal protection.

✅ Summary of the Five Alternatives

| Alternative | Key Benefit | Best For |

|---|---|---|

| Corrugated Boxes | Strong, protective, cost-efficient | Fragile/heavy products |

| Folding Cartons | Lightweight, customizable, print-friendly | Retail packaging |

| Sleeve Packaging | Elegant look with less material | Gift sets & cosmetics |

| Sticker + Universal | Low-cost, scalable, SKU-flexible | Startups, seasonal items |

| Hybrid Packaging | Balanced cost and aesthetics | Premium products |

3. Luxury Packaging Without the Luxury Price

Rigid boxes undoubtedly offer a premium presentation—but that prestige comes at a cost many businesses can’t or shouldn’t absorb. From higher material and labor expenses to increased shipping and storage inefficiencies, rigid packaging often creates challenges that outweigh its visual benefits, especially for fast-moving or cost-sensitive products.

The good news? There are smarter packaging options available.

By considering alternatives like corrugated boxes, folding cartons, sleeve packaging, sticker + universal packaging, and hybrid structures, brands can maintain a high-quality unboxing experience without breaking the budget. These options not only reduce production and logistics costs but also provide flexibility in design, storage, and sustainability.

Each alternative can be tailored to match your product’s needs—whether you prioritize strength, branding, visual appeal, or cost efficiency. And with the right printing techniques and structural design, even a basic box can deliver a luxurious impression.

In today’s competitive market, packaging isn’t just about looks—it’s about balance. A well-designed, cost-effective alternative to rigid boxes can enhance your brand while helping you scale smarter.