In premium paper packaging, the smallest details make the biggest impression. Whether you’re designing boxes for electronics, chocolates, or luxury gifts, the surface finish can dramatically affect how your product is perceived. One of the most effective techniques to enhance printed designs is UV coating, especially Spot UV.

This article explains what Spot UV is, how it’s used in packaging, the differences between thin and thick applications, and how it can be combined with embossing for even greater visual impact.

1. What Is UV Coating in Paper Packaging?

UV coating is a clear, liquid finish applied to printed surfaces and cured instantly using ultraviolet light. Once cured, the coated area becomes glossy, durable, and visually striking.

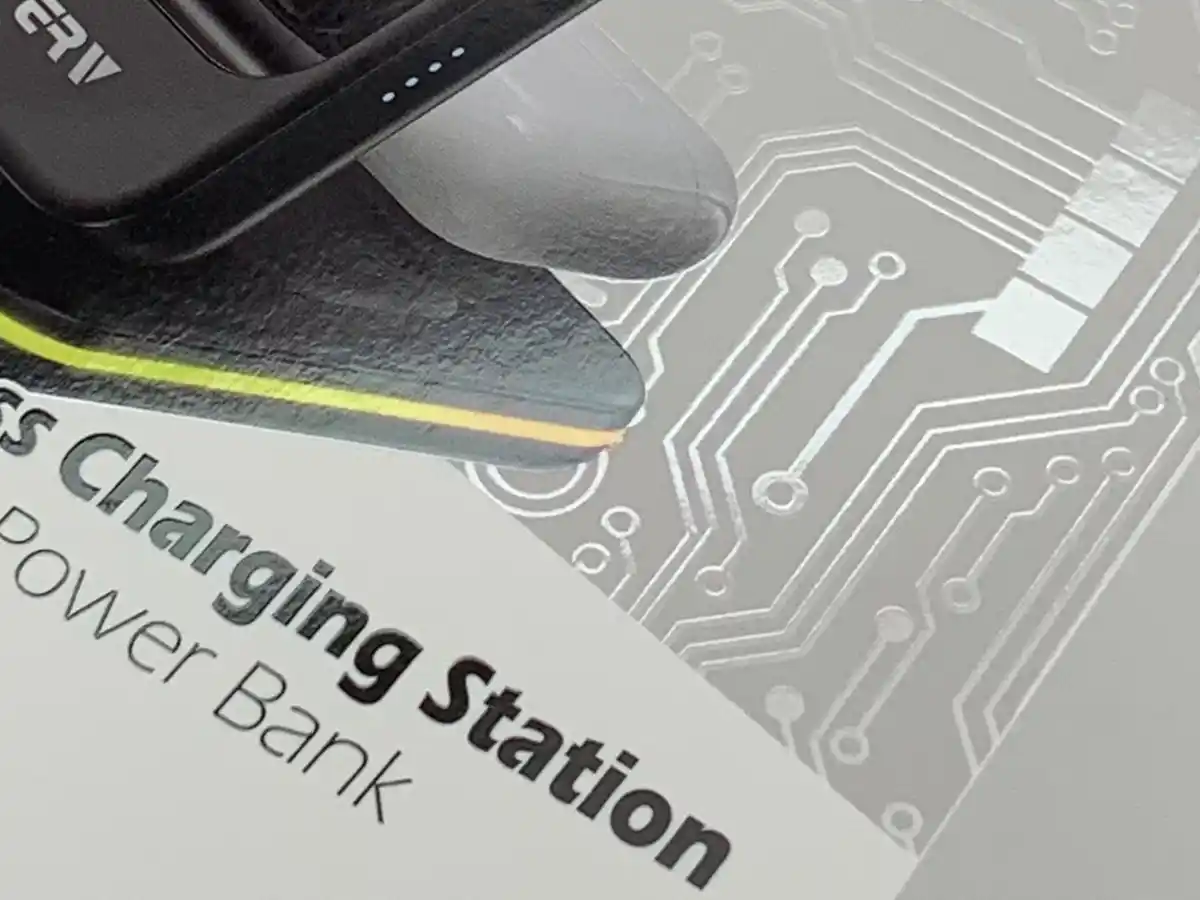

In packaging, the most commonly used technique is Spot UV — where the coating is applied only to specific areas, like logos, text, or decorative patterns. This creates contrast between coated and uncoated areas, adding depth and enhancing design visibility.

📌 Note: While UV can be applied in matte or gloss finishes, gloss Spot UV is by far the most popular due to its vivid shine and visual contrast.

2. Why Use Spot UV in Paper Packaging?

Spot UV is widely used in packaging to improve both aesthetics and functionality:

- Design Highlighting

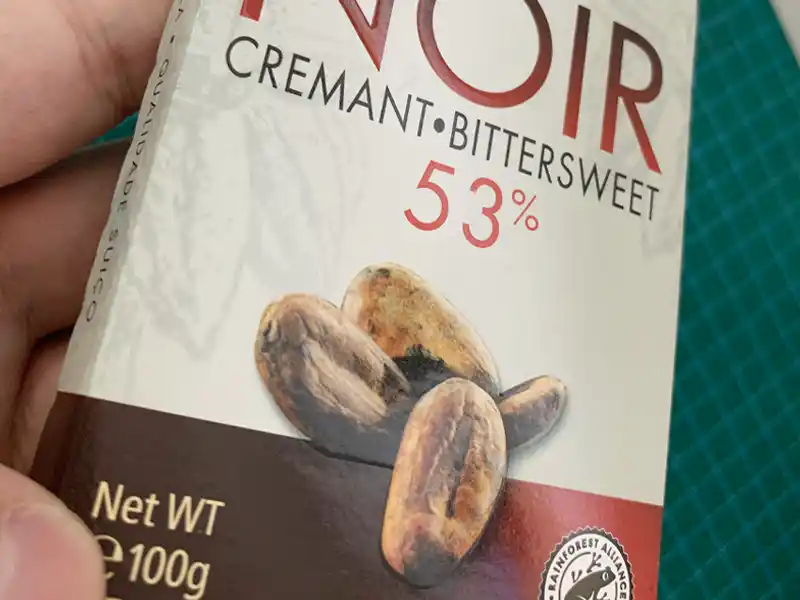

Spot UV draws attention to key elements such as logos, names, or taglines by making them pop with shine or texture. - Premium Look & Feel

The glossy effect enhances the perceived value of the packaging, which is especially important for luxury, gift, and retail products. - Protection

UV coating adds a protective layer that resists light scuffs and smudges, keeping the packaging clean during handling. - Fast Production

Since it cures instantly under UV light, Spot UV allows for efficient production workflows.

3. Thin vs. Thick UV Coating

Depending on the visual and tactile effect you want, UV coatings can be thin or thick:

- Thin UV Coating

This is most common. It offers a subtle gloss with minimal texture, perfect for sleek, modern packaging where detail is key without being overpowering. - Thick UV Coating

Thicker applications of Spot UV add noticeable depth and texture. These are ideal when you want a more tactile effect or to simulate raised surfaces.

✅ If you’re aiming for maximum contrast and dimension, embossing combined with Spot UV is your best option.

4. Embossing + Spot UV: A High-End Combination

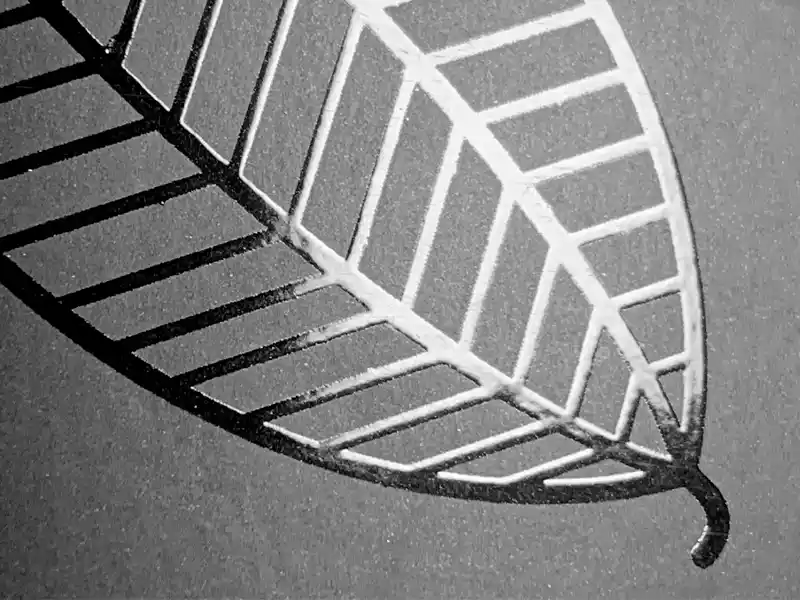

One of the most impressive finishes in paper packaging is combining embossing with Spot UV. This technique applies Spot UV to a raised (embossed) design element, making it both shiny and tactile.

Benefits:

- Creates a luxury feel that customers notice instantly

- Enhances brand recognition by making logos or names literally stand out

- Ideal for gift boxes, chocolate packaging, cosmetics, and premium product lines

This combination is often used when thick UV alone isn’t enough to achieve the desired impact.

5. Common Packaging Applications of Spot UV

Spot UV is especially popular in:

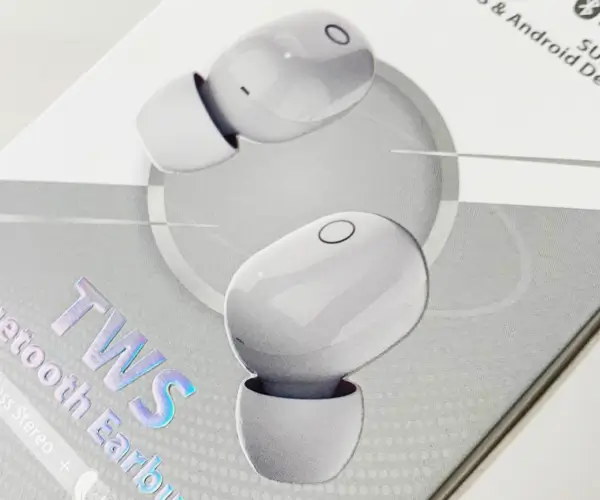

- Consumer electronics boxes – to highlight product name or icons

- Snack or food packaging – to draw attention to branding or illustrations

- Gift and specialty boxes – where visual appeal matters most

- Paper bags, labels, hangtags, and cards

- Patterned surfaces – Spot UV works great on matte backgrounds to create contrast

6. Design & Production Tips for Spot UV

If you’re planning to use Spot UV in your packaging, keep these tips in mind:

- Choose the right paper stock

Spot UV works best on smooth, coated paperboard — ideally above 300gsm. - Define your UV areas early

Mark them clearly in your artwork files using a separate UV layer. Avoid fine lines that may not register well. - Avoid overuse

Spot UV is most effective when used selectively to highlight — not overwhelm — your design. - Test with a prototype

Especially if you’re using thick UV or combining with embossing, request a sample to check registration and alignment. - Coordinate with your supplier

Ensure they have the capability to handle precision Spot UV and embossing accurately.

7. Conclusion

Spot UV is a versatile, cost-effective way to elevate paper packaging — whether you’re aiming for a clean, modern look or a high-end luxury feel. Its ability to highlight design elements, enhance brand presence, and add surface protection makes it a favorite in packaging design.

For deeper visual and tactile effects, combining Spot UV with embossing provides an elegant solution that appeals to both the eyes and hands of your customers.